hammer crusher circumferential

Rotor impact mill – sand maker with a vertical shaft

Unique crushing principle. The impeller rotor of the rotor impact mill is the only one of its kind worldwide. The high circumferential speed of the rotor results in an almost permanent gap between the tips of the horseshoeshaped hammers and the anvil ring.

crushers concrete grandfather

Jeffrey's Manufacturing History in Columbus. In 1876 my greatgrandfather, Joseph Andrew Jeffrey, aged 40, was a junior partner in the . crusher business, and before long it was selling more crushers for wood pulp, sugar cane. the sales to other industries like steel and concrete and automotive were much larger.

hammer crusher circumferential

hammer crusher circumferential. GRATE BASKET FOR HAMMER CRUSHERS . Traduire cette page. 24/06/1975 · Referring now to the drawings in detail, the grate basket according to the invention for a hammer crusher (not shown) comprises two segments and is arranged coaxially with regard to the rotor 1 which latter is connected to a rotatable shaft 2.

Calizamar uses crushing technology from Sonthofen to ...

· The highperformance crusher features a vertical shaft and delivers high crushing ratio as well as an excellent cubic particle shape. It is based on an impeller rotor that uses ' unique crushing principle: the high circumferential speed of the rotor results in an almost permanent gap between the tips of the horseshoeshaped hammers and the anvil ring.

Hammer and hammer impact mills

Hammer and hammer impact mills. Hammer and hammer impact mills are suitable for crushing soft to medium hard materials (degrees of hardness according to F. Mohs 2 – 5). For example: agglomerates, coal, limestone, gypsum and slag. They are designed for large throughput volumes and troublefree operation.

Roll Crushers / Granulators

Therefore, Roll Crushers or Granulators are far superior and more efficient than Chain Mills, Hammer Mills, Cage Mills and others. Moreover, the Bell Shaped Curve tells the story: To illustrate, we've designed our roll crusher for a gradual size reduction in one, two, or three stages per unit, depending upon the ratio of feed size to desired finished product size.

Hammer crusher

Hammer crusher, comprising a housing with a receiving and discharge craters, bearings for the shaft with the rotor and plate Belami with sharp edges, which hosted a screening grid, characterized in that the shank of the shaft is fixed to the hub with the blades of the fan placed inside the cochlea, the suction nozzle which is connected with undersize space discharge hopper and discharge ...

Mill (grinding)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

Analysis of simulation result by digital filtering ...

· In the hammer crusher, the crushing is performed through constant collision between the hammers and the materials. In order to observe dynamic characteristics of the hammer crusher after collision, the collision model is made as shown in Fig. 4.

hammer crusher circumferential

hammer crusher circumferential. Home; hammer crusher circumferential Lets Get Started with MINIGN Now Get Price. Request a Call Back. Contact us for product information, prices, services and other support. We will reply to you as soon as possible within 24 hours. Thank you!

Types of stone crusher machines

· Hammer crusher Figure c shows the hammer crusher, ... The crushed products are discharged freely along the circumferential space of the impeller and the liner. Roller crusher Figure g shows the roller crusher, the working part of which is two rollers rotating in opposite directions.

The Hammer Mill Machine

The Hammer Mill is widely used for coarse/medium grinding of minerals, foodstuffs, fertilizers, and chemicals. Raw materials as big as a few tens of mm are ground to an average particle size of roughly by the impact generated from the swing hammers traveling at circumferential .

Hammer crusher

Hammer crusher consists of a base 1, a housing of the crushing chamber 2 to which the cover 3, on the outer surface of the cover has a separatorcompulabel 4. The housing 1 is fixed to the motor 5, the shaft of which is equipped with an external fan 6 and hammer the rotor 7. Outdoor fan 6 provided with blades 8 on the periphery of the disc 9.

4 Types of Stone Crushers' Maintenance and Efficient ...

· Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone".

heating of crusher surfaces

hammer crusher circumferential. Crusher Nakayama Iron Works Get Price Comparing to conventional impact crusher the machine been able to increase circumferential speed to twice 60m/s and crushes the small materials that is previously hard to crush because of its small size HSI1A has...

RPM Rotor Impact Mill

The high circumferential speed of the rotor results in an almost permanent gap between the tips of the horseshoeshaped hammers and the anvil ring. The small gap width and the high energy input due to the circumferential speed result in a very high, targeted crushing ratio. Grain shape Rock crushing with the rotor impact mill produces a high

Installation and Trial Operation Requirements of Hammer ...

· The installation of hammer crusher should follow the following regulations: 1. The machine base assembly should meet the following requirements: The positioning pins between the joint surfaces should be fully assembled; The contact

Device and method for comminuting coarsely crushed ...

· Polysilicon is crushed with a minimum of manual and machine crushing steps by utilizing a large diameter roll crusher, the circumferential crushing surface of which is formed of a plurality of reversibly mounted, close fitting hard metal plates. Reproducible crushing along with such low metal contamination that subsequent cleaning of the crushed polysilicon is not necessary are both obtained.

Latest Posts

- مركز حجر بروساهان مصر

- استخدمت تعقب الكسارات المتنقلة في المملكة العربية السعودية

- قائمة شركة مناجم الفحم في دبي

- ماكينات صناعة الحصى في الجزائر

- معدات نقل كسارة الحجر

- آلة صنفرة القرص في مصر

- بحاجة إلى خطة عمل لإنشاء وحدة محطم

- طحن مطحنة الكرة خام الحديد

- المعدات المستخدمة لمعدات كربونات الكالسيوم 3 المملكة العربية السعودية

- من جهة ثانية آلة كربونات الكالسيوم في عمان

- تصميم كسارة صغيرة من السيليكا خط استخراج

- الشركة المصنعة لمعدات طحن الكالسيت

- cidarapids mvp450 كسارة مخروط كسارة

- وحدات كسارة الحجر في بنغالور

- المصنعين كسارة حجر في ناشيك

- tulasi table top wet grinder

- froth flotation floatation

- picture of a grinding machine

- manufacturing plant project report

- milling machinery milling

- main construction manufacturer malaysia

- jaw crushers price in australia

- 45 inch el jay cone crushers

- used concrete and brick machine peter

- cement grinder at harbor freight

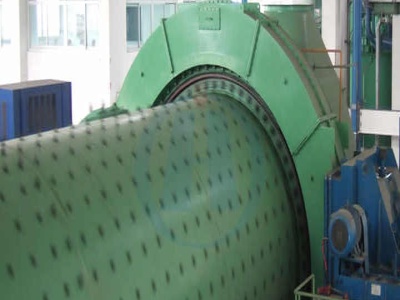

- ztmg ztmy tube energy saving mqy mqg ball mill

- combien coût de maintenance pour la carrière concasseur

- simon concasseur à cône en vente au royaume uni

- turmeric grinding producers

- used waste plastic pet bottle crushing washing drying recycling line