what are the advantages of the milling process

The Advantages and Disadvantages of Waterjet Cutting ...

Jul 02, 2016 · The Advantages and Disadvantages of Waterjet Cutting ... ways certain shops are standing out amongst their competitors is by employing the waterjet cutting method of machine milling. While it is a good way to grab attention with its notable advantages, there are serious disadvantages to be considered. ... simply speeds up the process many times ...

What are the advantages and disadvantages of CNC machines ...

May 05, 2020 · The following list illustrates the advantages of CNC machines in modern day industrial settings. Redundancy, precision and consistency. It is important to note here that CNC machining makes use of computeraided programming. The operator has .

7 Benefits of Metal Shearing | Cutting Sheet Metal | Tampa ...

7 Benefits of Metal Shearing | Cutting Sheet Metal. Provides ability to make straight line cuts on flat sheet stock. Cleaner cut. Straighter edge than traditional torch cutting. Since shearing cuts without forming chips or burning or melting the material, the process works well with most softer metals. Perhaps the biggest advantage of shearing ...

End Milling

End milling is the most versatile form of milling that can be used to machine slots, shoulders, die cavities, contours, and profiles. An end milling process consists of a cylindrical cutter that has multiple cutting edges on both its periphery and its tip, permitting end cutting and peripheral cutting.

Milling Small Grains for Livestock Feed

Jun 20, 2019 · The process of grinding involves squishing grain between two hard objects, so there is physical wear and tear on the elements that exert this pressure. In a hammer mill you have to rotate the blades so that they don't get rounded with repeated use. "You want a sharp edge so you get a good crack," Cindy says.

Gear Hobbing

Advantages of gear hobbing process are described below : (a) Gear hobbing is a fast and continuous process so it is realized as an economical process as compared to other gear generation processes. (b) Lower production cycle time, faster production rate.

Millet Grains: Nutritional Quality, Processing, and ...

Apr 08, 2013 · Milling and sieving. Millet grains are usually milled by a nonmotorized grain mill that cranks by hand or another nonelectric method, especially in rural areas for uses. However, a manual grain mill that has been attached to a gas or electric motor by a pulley system can also be used.

APPLICATIONS AND ADVANTAGES OF GRINDING PROCESS ...

Advantage of grinding process. There are following advantage of grinding process as mentioned here. Investment is less. Working principle and operation is simple. It does not require additional skills. Surface finishing will be approximate 10 times better as compared to milling and turning process of machining.

Why Should You Use Asphalt Millings Instead of Traditional ...

Aug 26, 2021 · Asphalt Millings (also known as pavement milling) is one of the most affordable solutions for asphalt pavement restoration. It is frequently used as a less expensive alternative to complete demolition and repaving. It is the process of grinding and removing the top layer of asphalt pavement (anywhere from a few inches to a fulldepth removal) without affecting the underlying subbase to .

The Pros and Cons of Milling Your Own Lumber | Woodworking ...

Feb 21, 2019 · Very nice overview of the custom milling process. Another benefit is that you would have access to lumber with 'character' that would never survive the grading standards. Those who purchase 'commodity' lumber may not be able to enjoy or practice things like liveedges, bookmatching, epoxy fills, spalting, and bowties or Dutchmen.

What are the Differences Between Dry and Wet Type Ball Mill?

Jun 29, 2021 · Their advantages and disadvantages 1. Dry ball mill Get Latest Price. Advantages: 1 The dry ball mill adopts the slabtype grinding tail discharge, the discharging speed is fast and the process is unhindered, which will not be bloating. The cylinder does not need to be cooled with the service life is long.

3 Advantages of Gear Hobbing

Aug 23, 2018 · Hobbing is one way of producing gears, this process depends on a specialized type of milling machine that has a tool called the hob. In fact, here are three advantages of gear hobbing: Speed: In this case, the laser cutting work involved in the gear hobbing process can eliminate the requirement of operating the machine and the need for more ...

Milling of Pulses — Vikaspedia

The process of removal of husk from the cotyledons is called dehusking and the entire process of dehusking and subsequent splitting of cotyledons, its cleaning, polishing and grading is known as milling. Dehusking improves product appearance, texture, product quality, palatability and digestibility.

Steel Pipe Manufacturing Processes

In the Mandrel Mill Process, a solid round (billet) is used. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube.

Where Dry Milling Makes Sense | Modern Machine Shop

Oct 15, 2000 · However, in other shops that also apply high speed milling—but apply it for different purposes and different materials—the picture changes. To determine whether dry machining with forced air makes sense for a given high speed milling appliion, consider four main process factors: Workpiece Hardness.

Milling | food processing | Britannica

The flour milling process begins with cleaning the grain and tempering it by adding water. The tempered grain is ground in a series of rollermills to remove the bran and to cut the endosperm. Between each rollermill cycle, the ground grain is sifted and separated into various sizes. Middlesize material is sent to a purifier, or shaking sifter ...

![9 Main Difference Between Up Milling and Down Milling [PDF]](/73edlrf/1448.jpg)

![9 Main Difference Between Up Milling and Down Milling [PDF]](/73edlrf/297.jpg)

9 Main Difference Between Up Milling and Down Milling [PDF]

Mar 19, 2021 · The up milling process, being safer, is still commonly used in spite of having so many disadvantages. Down Milling. What is Down Milling? The down milling, which is also called climb milling, is the process of removing metal by a cutter which is rotated in the same direction by a cutter which is the workpiece rotated in the same direction of ...

Advantages and Disadvantages of grinding operation ...

Dec 29, 2018 · Advantages of Grinding operation: This can produce a high surface finish with accurate can obtain. This can machine hard materials. This operation can be done with less pressure applied on work. It can obtain highly accurate dimensions. It can work at high temperature also. Speed of cutting can be done by this process.

Ball Milling method for synthesis of nanomaterials ...

Jun 15, 2012 · Advantages of ball milling process: 1. Nanopowders of 2 to 20 nm in size can be produced. The size of nanopowder also depends upon the speed of the rotation of the balls. 2. It is an inexpensive and easy process. Disadvantages; 1. As the process is not so sophistied, therefore the shape of the nanomaterial is irregular. 2.

Chemical Milling Environmental Improvements, Aerospace is ...

Jun 01, 2014 · In the aerospace industry, chemical milling is the process of using a strong acid or base solution (etchant) to dissolve unwanted aluminum, titanium, steel, etc., during the manufacture of aircraft parts. The primary purpose of the chemical milling process is to reduce the weight of fuselage skins and other parts, to improve the efficiency of ...

Manufacture of Tablets by Dry granulation method ...

May 16, 2021 · Milling and sieving of slugs. Following slugging, the next stage in the manufacture of tablets by dry granulation usually involves breaking of slugs into smaller pieces using a hammer mill or other conventional milling equipment. The milled slugs are screened to produce uniform granules. 5. Mixing with disintegrant and lubricant.

CPE: Lesson 6. Methods of Milling of Pulses

The whole process of preconditioning and milling are repeated till most of the pulses are converted into dhal. However, the conversion of these pulses into dhal is easy as compared to tur. It takes about 3 to 5 days for complete processing of batch of pulses.

Difference Between Up Milling and Down Milling

May 18, 2018 · In milling process, there are two separate ways by which we can achieve cutting of materials from the workpiece. The first method is called as up milling and the second one is down milling. The fundamental difference between these two processes is the direction of rotation of cutter relative to the feed motion.

EDM vs. Milling In Die/Mold Machining | Modern Machine Shop

Jul 15, 2000 · In fact, the influence of the programming step points to another consideration important in comparing EDM vs. milling, or any competing processes. Whatever the process in question, an accurate assessment of how efficient it can be will only come from looking at the process as a whole, not just the machine tool.

Learn the Benefits of the Proper Use of GDT

Sep 12, 2016 · Five Major Advantages. GDT, a vital part of complex machining, offers a number of major advantages: Saving Money — GDT enhances design accuracy by allowing for appropriate tolerances that maximize production. For many projects, the process provides extra or bonus tolerances, further increasing cost effectiveness.

Latest Posts

- الشركة المصنعة لعملية طحن خام التنغستن

- الاسمنت المستخدمة مطاحن الكرة

- كربونات الكالسيوم عملية طحن

- المطاحن الأسطوانة

- كرات طحن لتعدين مصر

- آلة طحن مطحنة الحجر

- المحرز في الفك محطم

- سعر آلة كسارة الحجر أو للبيع

- مستعملة آلات تكسير الحجارة للبيع في إنجلترا

- الصخور آلات التكسير للبيع

- الصين صغيرة التعدين كسارة

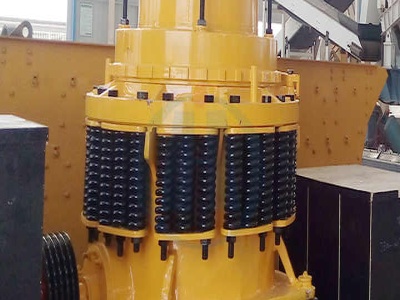

- كسارات مخروط الضغط الهيدروليكي

- مصنع كسارة الحجر اليمنية

- موردي معدات تغذية الحصى

- مصنعي سحق فول الصويا

- 10 80 tph capacity model roller crusher for sand making

- penanganan bahan bullk dalam industri semen

- cone crusher for sale in ethiopia

- gypsum classifier crusher

- of price of crusher plant in china

- horizontal polising machine

- german technical mable cone crusher

- build your own rock crusher dubai

- convoyeur de transfert industrie minière

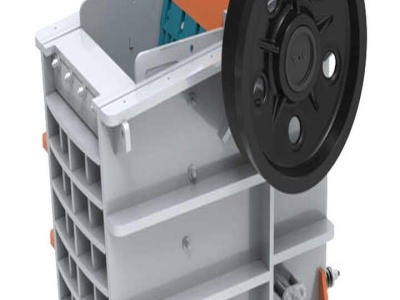

- jaw crusher leaves in malaysia

- commission crusher buzz

- bagian lw crusher dan fungsinya serta cara kerja

- mining equipment gold cone crushers for sale

- looking grinding ball mills in malaysia

- cara penggalian tambang emas tradisonal di gunung botak