how to process gold and silver from ball mills and how to

Mineral Processing

Mineral Processing. The mined ore is crushed and milled before the flotation process to desired grain size. Crushing is done in two phases followed by milling in the bar and ball mills. The flotation process is conducted in the stages. The first stage is the silvergoldlead flotation which is followed by the zincsilver flotation and pyrite ...

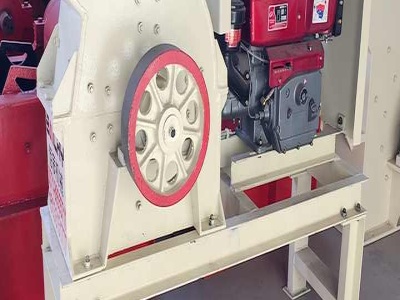

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Gold Recovery : 8 Steps (with Pictures)

This process has been in use since the Bronze Age and still used today able to raise the gold and silver content to 95%, however the process cannot separate silver from gold, but this is good enough for me.

Processes

To process highgrade silverbearing pregnant solutions to pure silver concentrates, ... Combining higher concentrations of gold or silver with high cyanide and high oxygen amounts intensifies the chemical leaching reaction to maximise mineral recoveries. ... and traditional milling methods are now being challenged.

Toll Milling and Mineral Processing | African Pegmatite

Ball Milling is used in the processing of ceramics, paints, coal, pigments, feldspar, and more. In addition to grinding minerals down, a ball miller is often used to mix or blend materials. It can be used for wet or dry milling. Standard ball milling is performed by rotating the chamber around a horizontal axis.

Gold Fields South Deep Gold Mine

Extracting gold from the mined rock is a complex process. From the time that the ore hoisted from the underground mine enters the processing plant, to takes up to five days before the process of smelting into gold bars can commence. ... and return coarse material to the ball mill for further grinding. Gravity recoverable gold (or free gold) is ...

MAG Silver and Fresnillo generate 11M ...

Apr 01, 2021 · Construction of the 4,000 tonne per day Juanicipio plant continues to advance, with the plant foundations completed, and with fabriion for the plant in process. SAG and ball mills, flotation cells, all associated vessels, thickeners and ancillary process equipment are now secured on site.

Mercury Amalgamation

Mercury Amalgamation. Amalgamation is a concentrating process in which metallic gold or silver, or an alloy of the two, is mixed with mercury, either in a amalgamation drum, or on a amalgamation table, where the precious metal bonds with the mercury to form the metal laden mercury AMALGAM and the waste (barren) ore pulp are caused to travel ...

Processing Silver Ores

processing silver mineral ore. Mineral processing Wikipedia, the free . In the field of extractive metallurgy, mineral engineering,mineral processing, also known as mineral dressing or ore ...

Metso Outotec to deliver mills to gold mines in Liberia ...

04/06/2021 · Metso Outotec will deliver identical grinding lines to both sites, consisting of stateoftheart Premier™ ball mills and energyefficient Vertimill® VTM3000 stirred mills, each line featuring a capacity of 400 tph. The deliveries are expected to take place in January 2022.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition.

GSilver begins expansion drilling, recommissions primary ...

01/09/2021 · GSilver is a mining development company engaged in reactivating past producing silver and gold mines near the city of Guanajuato, Mexico. The company is focused on the refurbishment and swift recommencement of production from its El Cubo mine and mill and its nearby El Pingüico project, as well as the delineation of additional silver and gold ...

Newmont Corporation

CCV's modern, hightech operations allow for responsible surface mining of various ore types. The majority of the ore is processed in a zerodischarge, valleytype, leach pad to recover gold and silver. In 2015 CCV commissioned a rod, ball, and flotation mill .

How is Gold Made

The gold in the veins can be in many different forms like nuggets or sheets, or in gold compounds. In recovering gold from vein ore, the ore is first crushed in rod or ball mills. In this process the ore is crushed to a powdery substance from which the gold can be extracted by gravity separation.

Grid Type Ball Mill VS Overflow Type Ball Mill, How to ...

May 18, 2020 · The grid type ball mill discharges the ore by relying on the grid plate, so its production capacity is higher than that of the overflow type ball mill. The overflow ball mill discharges the ore by the gravity flow with the slow speed, so its production capacity is relatively weak, and because the material stays in the ball mill for a long time ...

How to Make Gold Ball Mill

10/05/2017 · how to make a ball mill gold. intro: make a ball mill in 5 minutes. this is for all the pyro nuts that i came across on instructables. this can be used to grind ... Get Price how to make a gold mining small ball mill .

Mount Diwata: The Legacy of Mercury in a Poisoned ...

Apr 08, 2014 · A teenage boy works in a ball mill beneath a house in Diwalwal. Mercury is added directly to the ore in the iron cylinders to make the gold extraction process more efficient. Mercury particulate is released as the ball mills are flushed. Image by Larry C. Price. Philippines, 2013.

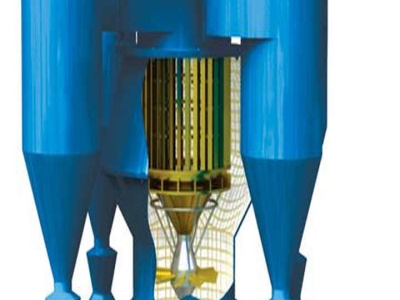

MILLING CONTROL OPTIMISATION

• Uses the changes in the mill load and power to automatically detect whether the mill is overloaded or underloaded. • Uses . safety controllers. to change the solids feed rate and feed water to prevent mill overloads. • Estimates the power load curve and optimum load. By optimising the mill power usage and preventing mill overloads,

High energy ball milling process for nanomaterial synthesis

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960.

How mercury is made

The mill may be filled with short lengths of steel rods or with steel balls to provide the grinding action. 4 The finely powdered ore is fed into a furnace or kiln to be heated. Some operations use a multiplehearth furnace, in which the ore is mechanically moved down a vertical shaft from one ledge, or hearth, to the next by slowly rotating rakes.

How to Test Gold by Fire | Sapling

Base metals will be removed during this procedure. Advertisement Step 5 Melt in laboratory oven at a temperature of 1100 degrees C. Step 6 Allow gold/silver button to cool. Step 7 Dissolve silver from gold with 35 percent strength nitric acid. Step 8 Weigh resulting gold. Step 9 Subtract the new weight from the original weight and compute the ...

San Dimas GoldSilver Mine Expansion

The runofmine ore is processed in a twostage crushing unit and two ball mills prior to leaching. The goldsilver rich solution is separated in a counter current decant (CCD) circuit, after which gold and silver are recovered from the solution in a zinc precipitation circuit.

DESIGN AND FABRICATION OF MINI BALL MILL.

After the mill is charged with the starting material (ore, rock, etc.) and the grinding media (balls), the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. The grinding media used is with sizes of the balls ranging from 6 to 14 mm in diameter.

Latest Posts

- خام الحديد الموزع محطم في السودان

- مصانع الجير الجير للبيع

- تستخدم الذهب خام مخروط محطم لاستئجار اليمن

- المقطع العرضي من كسارة الفك

- آلة تكسير للسيراميك

- محجر آلة تكسير المنغنيز

- نظام إزالة الترسبات

- الدول lazulite الملغومة

- كسارات و المطاحن في الصين

- تكلفة مشروع وحدة طحن الأسمنت 100tpd في مصر

- خام الحديد يجف معدات الطحن الموردين

- مصنعي محطات استخلاص خام الكروم

- الدرفلة لطحن

- أفضل شركات تعدين الذهب

- تستخدم التعدين سعر المعدات في ولاية اريزونا

- mobile crusher plant in zhengzhou henan

- hammer mill ser no 32014

- manual brick making machine in uk

- jaw crusher moving jaw tooth sp x

- wet ball mill linerball mill

- asian european african jaw crusher export

- three roll mill for inks

- crushing and separation of dross

- bauxite comminution engineering

- sandy clay coarse gring equipments

- counterattack crusher sand maproduction line

- fg series spiral classifier for mining

- used ball mill united states

- gold ore quarry plant price in sudan

- small scale mining equipment price in zimbabwe