vertical ball mill design

Lab ball mills,Lab Powder Equipment,Lab Glove Box ...

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in design, manufacture, and sales of all kinds of lab ball mills.

Planetary Ball Mill Manufacturers Suppliers India

In addition, these planetary ball mill machines feature ergonomic design, simple operation, easy cleaning and guarantee safe clamping of mill jars. These machines come in different grinding volumes; 2 liters, 4 liters, 8 liters, 10 liters, 12 liters and 16 liters and more. We manufacture planetary ball mill in both Vertical and Horizontal types ...

Vertical Roller Mill,Verical Roller Mill Types

Verical Roller Mill. Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design.

Vertical roller mills: The new leader in grinding technology

Oct 11, 2019 · The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change considering that ...

The Working Principle of Hammer Mills (Stepbystep Guide)

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same.

Coal mill, gypsum mill, clay mill, etc. | Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it .

Vertical roller mill

Features CHAENG GRM vertical roller mill has the integrated functions of grinding, drying, powder selecting and conveying, with innovative technologies of high grind efficiency, strong drying ability, low noise, low power consumption and simple process. GRM vertical roller mill is innovative, environmental friendly and efficient, and it has won a number of Chinese technical patents.

Limestone Grinding Ball Mill (CL) | Union Process

The CL5 Stirred Vertical Ball Mill for Limestone Grinding is a smaller version of the production sized CL Series Mills. It is ideal for research, scaleup and smallscale production. This mill will process in the range of 200500 pounds of limestone per hour and is equipped with a variable frequency drive (VFD) and a 15 horsepower inverter ...

VRPM – AMCL Machinery Limited

VRPM. The Vertical Roller Pregrinding Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co. Ltd. Japan. These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Raw meal Grinding. We have over two decades of experience in supply and installations of ...

Simaie Sanate Spadana

Design optimized for maintenance ... Compared to ball mills, the SIMA mill can produce better or equivalent cement quality. SIMA MILL. Designed for economically grinding a variety of cement types. ... Raymond mill Vertical Roller mill Ball mill Classifier Published: ...

Jet millairflow mill,air jet milling machine,jet mill ...

According to the design structure, Jet Mill can be roughly divided into: fluidized bed Jet Mill (including vertical and horizontal types); Disc Jet Mill. ALPA could produce jet mill with big capacity of 10T/H, could also produce mini milling machine/small vertical mill for laboratory. Equipped with fully automatic PLC control.

Alpine ANR Vertical Wet Media Mill | Hosokawa Micron ...

Alpine ATR Vertical Dry Media Mill The Alpine ATR Vertical Dry Media Mill is ideal for the dry production of superfine mineral powders finer than 10 µm. Alpine AWM Table Roller Mill The Alpine Table Roller Mill AWM features conical grinding rolls for highpressure comminution. Alpine SO Super Orion Ball Mill The Alpine SO Ball Mill is capable of grinding many hard materials down to D80 = 2 µm.

Overview of our mills · Christian Pfeiffer

Vertical mills Flexible mills with integrated separator. The vertical mill enables high energy economy, and convinces with low specific wear values. Drying of the feed material, grinding, separating, and material transport take place inside the mill. It is thus especially well suited for grinding products with high proportions of wet components.

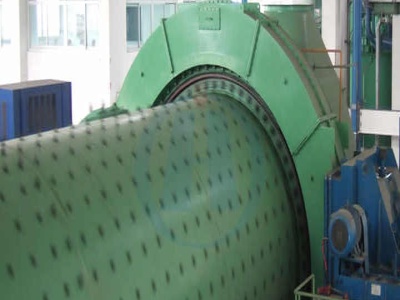

Ball Mill Used in Minerals Processing Plant | Prominer ...

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

Business Plan For A Crushing Stone Machine

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% .

A study of comminution in a vertical stirred ball mill.

Using a 5 litre batch mill, an experimental programme was designed to study the comminution characteristics of the stirred mill. A factorial design was prepared with the following parameters, which influence grinding in the stirred ball mill: pulp density, pin tip velocity and ball density .

Air Classifier Mill | Hosokawa Micron Ltd

Air Classifier Mill Specifiions. Available in a range of sizes from 2 kW Lab RD version up to 600 kW. Range also includes two special designs, ACM EC (easy clean) with CIP capability and ACM SB (split body) where the mill cover opens to allow both body sections to swing open giving unhindered access to internals.

Latest Posts

- كسارات الحجارة للبيع في العراق

- مناجم كسارة الأردن

- آلة طحن موزع دبي

- تعدين الذهب الشركات المصنعة للمعدات

- صور كسارة الفك سيدني

- محطة كسارة الحجر المستخدمة في الجزائر

- مصنعي كسارة بما في ذلك

- مطحنة ريمون الأردن

- آلة التكسير المعدنية في باكستان

- حيث يمكن إهدار مسحوق كسارة الحجر

- خام الحديد لكل طن متري مبلل

- مصغرة آلة محطم معدل

- تهتز الشاشة المصنوعة في إيطاليا

- تكلفة الآلات كسارة الحجر

- جائزة آلة كسارة الحجر

- ore beneficiation plant for lead ore high production

- rotary knife grinder

- beralih grease jaw crusher

- cultured marble manufacturing process

- mobile reliable performance cone crusher

- ball mill for slag of 50tph

- supplier jaw crusher di indonesia in indonesia

- coal handling system in thermal power plant in india

- pill crusher travellingpill crusher wholesalers

- utilisé des concasseurs à machines en espagne

- list of crusher plant at kabrai uttar pradesh in lucknow

- copper production line

- detail atau stone crusher indusrty sand making stone quarry

- grinding and crushing of ores quarry crusher

- scissors shears gingher