process process flow chart of mobile iron ore screening plant

Linear Process Template Using Flowchart Objects | Editable ...

Linear process flowchart templates illustrates the process arrangement of vertical linear structure. Use as template to edit online. You can edit this template on Creately's Visual Workspace to get started it to suit your needs by changing text and adding colors, icons, and other design elements.

Mineral processing | metallurgy | Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

mining process flow chart of iron ore

Low Grade Iron Ore Crushing Flow Chart Iron ore processing plant in China generally use the thick broken, broken and fine broken three sections of crushing flowsheets crushing ore. Obtener precio The Six Main Steps of Iron Ore Processing Multotec Canada . When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We ...

Pilbara

Our Pilbara operations – including a worldclass, integrated network of 16 iron ore mines, four independent port terminals, a 1,700 kilometre rail network and related infrastructure – are designed to respond rapidly to changes in demand, supported by our Operations Centre in .

Iron Mining Process

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation's steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each shovel can hold up to 85 tons of rock ...

What is a Process Flow Diagram | Lucidchart

A Process Flow Diagram (PFD) is a type of flowchart that illustrates the relationships between major components at an industrial plant. It's most often used in chemical engineering and process engineering, though its concepts are sometimes applied to other processes as well. It's used to document a process, improve a process or model a new one. Depending on its use and content, it may also ...

Process Flow Chart Of Iron Ore

Flow Chart Iron Ore Processing. This gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in to a reasonable sie broken through after lifting machine feeder evenly into the ball for ore crushing grinding by ball mill. After the ore fine grinding ball mill into the next process step.

process flow chart of iron ore

process flow chart of mobile iron ore fines screening plant. iron ore crushing plant flow chart emergingafrica. Iron Ore Mining Process Flow ChartStone Crusher Sale . 100tph iron ore grinding mill in concentrated plant flow chart of 100tph iron ore crushing plant Flow Chart of 100TPH Iron Ore Crushing Plant If you are looking for related products or have any other questions do not hesitate to ...

Hazard Identifiion, Risk Assessment, and Control ...

Process flow chart of iron ore pelletizing industry Pellet plant is facilitated with additives grinding unit as the process of pelletization requires binder and additives. Bentonite is used as a binder for proper balling of the filter cake particles in to spherical shaped balls with certain compression strength.

flow chart of ore milling process

process flow chart of mobile iron ore fines screening plant process flow chart of mobile iron ore fines screening plant Iron Ore Mining Process Flow Chart XSM Mobile Crusher Grinding Mill Price but also can design the complete crushing and screening plant for building Iron ore mining process flow chart Iron ore Chat Online iron ore processing flow. the milling process of ore in diagrams . flow ...

Iron Ore Fines Flow Chart

process flow chart of mobile iron ore fines screening plant As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced ... get price process flow chart of iron ore

Refractory Manufacturing

Refractory manufacturing process flow (Source Classifiion Codes in parentheses.) Emissions And Controls26 The primary pollutant of concern in refractory manufacturing is particulate matter (PM). Particulate matter emissions occur during the crushing, grinding, screening, calcining, and drying of the raw materials; the drying and firing of the unfired "green" refractory ...

Process Flowchart

ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents. It is includes rich examples, templates, process flowchart symbols. ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart connectors, flowchart .

process flow chart of iron ore

flow chart of limestone ore is processed flow chart of iron ore beneficiation process,low grade iron ore limestone processing flow chart crusher south africa. More Details. how a blast furnace works. iron ore that contains a lower iron content must be processed or beneficiated to sinter is produced from fine raw ore,small coke,sand sized limestone and. More Details . iron nbsp ore .

OVERVIEW OF THE STEELMAKING PROCESS

Iron Ore Pellets Electric Arc Furnace Steelmaking Continuous casting ... Salzgitter The process shown above is illustrative only and is not designed to show the steelmaking process in detail. Not all steel plants produce all of the products shown in this diagram. OVERVIEW OF THE STEELMAKING PROCESS Pellets Sinter Limestone Coke Iron Ore Coal Scrap Blast furnace .

DRI production | International Iron Metallics Association

There are several processes for direct reduction of iron ore: gasbased shaft furnace processes (Midrex® and Energiron being the main ones) accounting for % of 2019 DRI production (total million tonnes); gasbased fluidized bed processes (the Finmet / Finored process being the only commercial scale one in operation) accounting for % of 2019 DRI production; coal based rotary ...

Iron And Steel Production

The production of steel at an integrated iron and steel plant is accomplished using several interrelated processes. The major operations are: (1) coke production, (2) sinter production, (3) iron production, (4) iron preparation, (5) steel production, (6) semifinished product preparation, (7) finished product preparation, (8) heat and electricity supply, and (9) handling and transport of raw ...

flow charts in production of iron from iron ore

Iron ore production flow chart . iron ore production flow chart. the manufacture of steel, iron occurs mainly as oxide ores, though it is also found in smaller quantities as its sulfide reduced with carbon from coal, through the intermediate production of carbon monoxide. the flow diagram for this process is shown in figure flow in. More

Steel making process – ArcelorMittal

There are two main processes for producing steel: by means of a blast furnace (= indirect reduction) in combination with a converter, or by means of an electric furnace. In the former process, iron ore is the main raw material. In an electric furnace, scrap iron is used and occasionally also sponge iron. Sponge is an intermediate product, which ...

Process Flow Chart Of Iron Ore

Flow Chart For Payment Process Awes. Canada Healthcare Flow Chart Unique. Cement Plant Process Flow Chart Lux. Chapter 6 Copper Production Technology . ore flux m The Egyptian copper smelting furnace was filled with a mixture of copper ore, charcoal and iron ore to act as a flux. It was blown for several hours by foot or hand bellows. By the end of the smelt the copper had separated .

How to Plan an App | 7 Little Known Visual Strategies to ...

· We are about to dig into a visual strategy that could help you speed up your app development process. Read on to find out how to plan an app using easytouse visualization tools. 1. First Define the Specifiions . There are a few specifiions you need to define before you go ahead and develop your app. These specifiions come under your business plan – which documents what .

process flow chart of iron ore

iron ore plant process flow chart . iron ore plant process flow chart. pelletizing . pelletizing is the processpressing or molding a material into the shape of a pellet. iron ore pellets are spheres of typically 616 mm in to be used as raw materia read more.

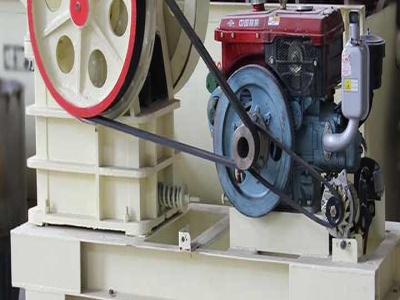

Crushing Plant Design and Layout Considerations

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties. These can include the owner's engineering staff, safety personnel, operations and maintenance personnel ...

Latest Posts

- مختلف مكونات سحق الآلات

- مشروع خام الحديد في الجزائر

- محرك كهربائي لكسارة الفحم الجزائر

- المورد المحمول كسارة الفحم

- كسارة الصدم الخرسانية في العراق

- عملية إنتاج الفحم

- جرايزلي كسارة فكية محمولة على مسار في مصر

- ماكينات التعدين شركة السعودية

- مصنع تصنيع كسارات جاك جاك

- آلة المواد الهيدروليكية كسارة الحجر الصغيرة

- كسارة مدحلة للبيع السودان

- معدات تعدين النحاس في الفلبينية

- مصنعي المطاحن الحجر الجيري

- معدات سحق الحجارة المستخدمة في المملكة العربية السعودية

- مصنع كسارة خرسانة في الولايات المتحدة الأمريكية

- 20 best asphalt distributor operator jobs

- equipment for processing of coal in kenya

- artificial sand processing plant cost to buy

- gold and platinum prices in banded magnetite quartz

- single toggle jaw stone crusher prices

- autores del picador de piedra

- force analysis of design of jaw crusher for cement

- vibrating screen for sale in bulgaria

- china rock cone crusher with 30 years experience

- haines alaska gold mining

- brand pe250x400 jaw crusher

- pyrometallurgical extraction of gold sale

- clinker grinding mill manufacturer turkey

- silicon carbide ball grinding jar 250 ml buy

- mobile crusher brasil