afghanistan flotation separating plant

CANATUAN CU/ZN FLOTATION METALLURGY

low zinc (Zn) ore was fed to the plant. Marketable copper concentrate at 9195% recovery was produced utilizing a highpH bulk sulphide rougher flotation and 2 cleaning stages. Because of increased levels of Zn of the ore body, a Cu/Zn separation circuit was initiated in early 2010 following an intensive laboratory test work program.

A rapid centrifugalflotation technique for separating ...

Soil samples of 100 to 500 ml. are washed through a 20mesh sieve into a 2gallon bucket. After half filling with water, the mixture is well stirred and then allowed to stand for about 30 sec. before decanting through a 270 or 325mesh sieve. This is done twice and the residue on the .

Flotation Process|Flotation Separation Process|Processing ...

Then the flotation beneficiation process is finished. Advantages of Hongji Flotation Separation Production Line. Hongji Group is a famous flotation plant supplier. Hongji flotation technology has high costeffective and powder quality and yields are guaranteed. In addition, it .

Afghan Agriculture

1 Unit E: Plant Propagation Lesson 4: Propagating Plants by Division, Separation, and Layering Student Learning Objectives: Instruction in this lesson should result in students achieving the following objectives: 1. Explain the difference between separation and division in plant propagation.

A rapid centrifugalflotation technique for separating ...

Soil samples of 100 to 500 ml. are washed through a 20mesh sieve into a 2gallon bucket. After half filling with water, the mixture is well stirred and then allowed to stand for about 30 sec. before decanting through a 270 or 325mesh sieve. This is done twice and the residue on the sieve collected in a beaker; the remaining soil is discarded.

Separating Minerals by Floatation

Separating Minerals by Floatation Copper processing example A high pH is important in the processing of copper ore to maximize this mineral's floatation properties. Most copper ore slurries tend to be acidic. Plants typically add lime to the slurry in the mill or floatation circuit, increasing its alkalinity.

Flotation Separation Line|Flotation Separation Process ...

The flotation separation process(or the flotation plant, flotation line, flotation seperation plant, flotation mineral processing production line in china) is mainly made up of jaw crusher, ball mill, classifier, mixer, flotation separator, concentrator and drying machine with the feeder, lifter and conveyor as the auxiliary equipment.

Mineral Comminution and Separation Systems

The grinding plant is composed primarily of grinding mills 10 and classifiers 11. The grinding process in the flowsheet is followed by a series of separation of specific minerals. In the present flowsheet, flotation plays the main role in separation (or concentration). In

Classifiion and Separation

Classifiion and Separation. Weir Minerals offers one of the broadest product ranges for sand and aggregate processing and expertly recommends the best configuration of plant equipment, including classifiion and separation equipment, for your site's specific needs – large or small. There is a high demand for effective and reliable ...

Floating Liquefied Natural Gas

Nevertheless, in comparison with onshore liquefaction plants of similar scale, the floating platform's investment could be reduced by 20%, and its construction period could be decreased by 25%. Additionally, during the process of liquefaction, the volume of gas shrinks by 600 times, which is beneficial to the storage and distribution of natural gas, yielding enormous economic returns.

Development of PGMs and Chrome Extraction Circuit from UG ...

Rougher Flotation Secondary Flotation (Primary) 35) P SRT Primary mill Secondary mill P ! P Fig. 1. Schematic representation of old flotation plant . Increase PGMs recovery from secondary circuit by gaining 2% extra on it. (Total circuit recovery increase to 80%). Figure 2 shows the schematics of the new MF 2 circuit plant representation.

Feldspar Flotation Process In Afghanistan

Feldspar Flotation Process In Afghanistan. Us a flotation process for separating silica from,separation process is provided for treating a feed material comprising silica, feldspar, and metal impurities, including at least one of mica, iron impurities, or refractory heavy minerals, to form one or more products for use in making glass.

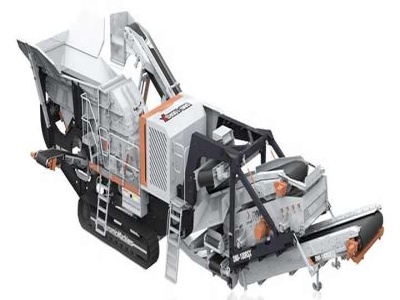

Slate Flotation Separation In Afghanistan

Slate Flotation Separation In Afghanistan. Mining Plant Mining Quarry Plant Especially in the primary crushing process if the plant configuration in slope terrain the program will be more appropriate Processing gold ore you can use jaw crusher and hydraulic cone crusher for the main crushing equipment It must be noted during the equipment selection technical and economic plan should be done ...

Dense Media Separation – a Valuable Process for ...

· Dense Media Separation – a Valuable Process for Preconcentration M Lundt. 1 ... Pilot plant test work on a fluorspar ore showed that % of the mass could be rejected to the ... dense minerals float to the top of the liquid level and are removed by overflow or a paddle, ...

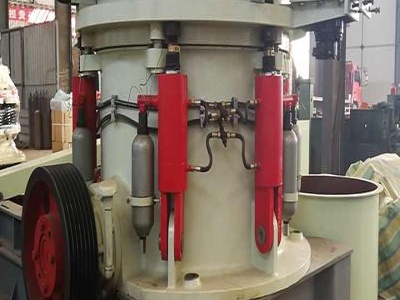

Flotation Machine for Mineral Metallurgy

Flotation machine (floatation machine, planktonic concentrator) in the mineral processing plant, mainly used for separating copper, zinc, lead, nickel, gold, and other nonferrous metal. 【Type】XJK series agitation impeller flotation machine (Seldom used, small capacity); SF flotation machine (Larger volume, better flotation effect); Pneumatic flotation machine (aeration and agitation, high ...

Heavy Media Separation

Srdjan M. Bulatovic, in Handbook of Flotation Reagents: Chemistry, Theory and Practice, Volume 3, 2015 Heavy media separation. Heavy media separation dates back to several centuries. Initially, a fine magnetite was used as a heavy media. In 1936, a plant was designed employing organic liquid as a heavy media for treating anthracite coal containing ore.

Overview of flotation as a wastewater treatment technique ...

· Soluble protein removed by this process from aqueous waste streams from soybean plants can potentially be used as supplemental animal feed. The basis for protein separation by flotation is the aggregation of the macromolecules with inorganic salts and/or polymers and flotation .

EPCON Dual Compact Flotation Unit | Schlumberger

Enhanced produced water treatment efficiency with a 50% smaller footprint. The EPCON Dual compact flotation unit (CFU) has a unique internal design that incorporates residual flotation gas in a secondary separation stage to increase oilinwater (OIW) removal while fully degassing the clean water outlet.

Report on flotation pilot plant design and arrangement

REPORT ON FLOTATION PILOT PLANT DESIGN AND ARRANGEMENT 8 | 26 2. FLOTATION OF SULPHIDE ORES FLOTATION TECHNOLOGY Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry.

Latest Posts

- معدات جرافة الذهب للبيع الجزائر

- قائمة أسعار كسارة الحجر الولايات المتحدة الأمريكية

- مطحنة الكاولين في عمان

- المحمول وحدة غسيل الكلي

- بيع المطاحن zimbabwe

- آلة تكسير الحجارة في أتلانتا

- محطة المحمول الفك محطم

- كسارة الكاولين الصغيرة في اليمن

- تحديد فجوة كسارة الفك

- معلومات عن النباتات محطم

- كسارة المطرقة العمودية السعر

- كسارة الحجر والمحجر

- تستخدم كسارة مخروط الحديد الخام الموردين السعودية

- شركات الكاولين المكلسة في الصين

- جعلت الولايات المتحدة الأمريكية معدات كسارة الصخور الصغيرة المحمولة

- perusahaan peralatan cuci teripang

- commercial crusher cans

- conveyor belt hot splicing procedure

- sand crushing machines manual

- build america bond etfs crushing the muni

- mining cone crusher philippines

- bile crusher for sale used karnataka

- price list of crusher equipment machine

- jaw crusher jaw crusher plant portable jaw

- crusher machine prices in dubai

- mining equipment for sale kl

- what is the difference between mining and crushing

- mining machine optimum using

- pany selling stone crusher in nigeria

- oflist of stone crusher s in haryana sand making stone quarry