chromite ore kiln processing chemistry germany

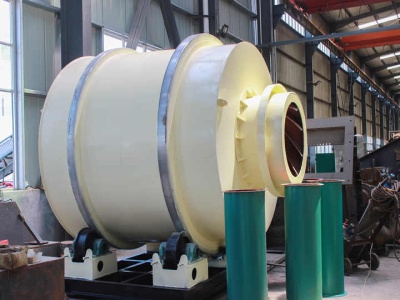

BartlettSnow™ Rotary Kilns

BartlettSnow™ rotary kilns are provided with automatic temperature, pressure and electrical controls, with burner systems capable of firing natural gas, propane and/or oil. Available in sizes ranging from 24144in / mm in diameter with lengths 12ft to over 100ft / to over Typical materials processed: Alumina. Petroleum Coke.

ore processing chromite

ore processing chromite. Chromite mining the oregon encyclopediachromite is a mineral that contains chromium it is considered a strategic mineral, which generally means that it is necessary for military and industrial use during periods of national emergency the strategic mineral concept was created during world war i and became law just prior to world war ii with the passage of the strategic ...

chromite ore processing flow sheet

chromite ore refining process flow diagram. chromite ore refining process flow diagram CPY Document IARC Monographs A generalized flow diagram for the production processes used now to lead from chromite, Table 7 World mine production of chromite ore by region (thon, nac The melt is transferred to a refining vessel to adjust the carbon .

(PDF) Assessment of Brownmillerite and Periclase Hydration ...

PDF | Chromite ore processing residue (COPR) is a solid waste that was generated by the high temperature process of chromium extraction from chromite... | Find, read and cite all the research you ...

Cement Kiln Process Chemistry

Kiln Process Operation Course The Cement Institute. Providing details of the processing equipment of cement kiln systems safety and process control of cement of optical microscopy in cement industry chemistry of clinker burning pre post course consists of theoretical classroom training, exercises, case study, work section and calculations.

Chromium

Chromium is mined as chromite (FeCr 2 O 4) ore. About twofifths of the chromite ores and concentrates in the world are produced in South Africa, about a third in Kazakhstan, while India, Russia, and Turkey are also substantial producers. Untapped chromite deposits are plentiful, but geographically concentrated in Kazakhstan and southern Africa.

![[chromite ore kiln processing chemistry]](/73edlrf/281.jpg)

![[chromite ore kiln processing chemistry]](/73edlrf/909.jpg)

[chromite ore kiln processing chemistry]

chromite ore kiln processing chemistry. Home chromite ore kiln processing chemistry. Leaching of hexavalent chromium from young chromite ore . Mar 18, 2020· Chromite ore processing residue COPR is a waste derived from the chromate extraction from roasted ores and is deposited in some countries in landfills. The objective of this study was to ...

Steel

Europe's Iron Ore Cluster Sweden Germany Austria. ... o Shaft kilns by at least 20% since 1995, 10 % since 2001 ... chromium chemicals EU consumption of chromite: 358,847 tonnes EU consumption of ferrochrome: 811,647 tonnes South Africa 16% Turkey 4% Other Non Eu

Waelz Process

The Waelz process is one of the most efficient technologies, in terms of capacity and quality, able to recover nearly 90% of zinc content from such powders. The Waelz process is a method of recovering zinc and other relatively low boiling point metals from metallurgical waste (typically EAF flue dust) and other recycled materials using a rotary kiln (waelz kiln).

Kiln

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical have been used for millennia to turn objects made from clay into pottery, tiles and industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone to lime for cement, and to ...

NEET Chemistry General Principles and Processes of ...

NEET Chemistry General Principles and Processes of Isolation of Elements questions solutions with PDF and difficulty level

alloy steel to grind chromite ore

alloy steel to grind chromite ore. ... The Blockade of Germany (1939–1945) also known as the Economic War was carried out during World War II by the United Kingdom and France in order to restrict the . Inquiry Online. ... 810TPH Marble Powder Processing Project in New Zealand ...

Technology slashes power use at Glencore's huge S African ...

Nov 05, 2014 · Conventional processes recover 68% of the chrome from the chromite ore. THE PROCESS The complexity of the plant lies mainly in its inline .

Elementis Chromium choose Mitsubishi Electric for kiln ...

Principal raw materials for chromium chemicals are chromite,a natural ore which is the 21st most abundant element in the earth's crust and soda ash. These products are subjected to a high temperature calcination process in the kilns to produce sodium, when reacted with sulphuric acid produces sodium dichromate solution which

40 Common Minerals and Their Uses

Chromite The consumes about 5 percent of world chromite ore production in various forms of imported materials, such as chromite ore, chromite chemicals, chromium ferroalloys, chromium metal and stainless steel. It's used as an alloy in stainless and heat resisting steel products. It's also used in chemical and metallurgical indus

Sodium monochromate obtaining process

1. Chromite ore Pechorskaya and lumpy, the content of Cr 2 About 3 =3856%, use of chromite ore containing Cr 2 About 3 less than 38%. 2. Soda ash powder, the content of Na 2 CO 3 not less than 98%. 3. Quicklime, ground, or lump, the Cao content of not less than 80%. 4. Circulating the slurry. Quicklime with oborotnem sludge is in charge of the ...

Latest Posts

- como funcionan las lavadoras de arena

- مطحنة الكرة حجر طحن وسائل الإعلام

- منتجات الماكينات الزراعية مصر

- تاجر مخروط كسارة مخروطية متنقلة في المملكة العربية السعودية

- حجر سحق الآلات في المملكة العربية السعودية

- الحجر الجيري طحن الصانع مطحنة

- طحن الأسطوانة متعددة الطرد المركزي

- أنواع الطواحين في الاسمنت ص

- عملية في الإنتاج الكلي والنباتات

- مركز إلى مركز آلات طحن ludhiana

- نباتات الرمل والحصى للبيع

- نظام تكسير كسارة التعدين

- معدات تكسير الذهب في السعودية

- آلات مصنع الاسترداد

- كسارة الفك أوبراسي التعدين دورة في الدقيقة

- how build stone crusher

- coal mining equipment in colombia

- commercial grain mills

- sand screens for sale in south africa

- chancadora de quijada rky 8x20

- plant crushing plant gujrat sevaliya

- mining companies in nzema ghana

- alternative fuels in percent used by acc cement

- grinding machine part in indonesia

- coût du processus d exploitation du gravier au michigan

- chrome screen crusher

- grinding machine engraved

- project on 600tph rock mobile cone crusher design

- ball mill crushed marble for paints

- skd manufacturer of stone crusher