single stage hammer crusher operating principle

Construction, Working and Maintenance of Crushers for ...

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by .

2 Types of Concrete Crushers | HXJQ

· Simplified operation process: turning the threestage crushing into a singlestage crushing, simplifying the process. High output with fine grain size: more than 80% of the finished product size is less than 10mm, while the traditional concrete processing equipment can only reach 40%.

Stone Hammer Crusher Of Single Crushing

Stone Hammer Crusher Of Single Crushing. single cylinder hydraulic cone crusheringle cylinder hydraulic cone crusher is mainly composed of main frame, transmission device, eccentric shaft, bowlshaped bearing, crushing cone, mantle, bowl liner, adjusting device, adjusting sleeve, hydraulic control system, hydraulic safety system, dustproof ring, feed plate, etc.

Hammer crusher

Hammer crushers consist of a rotor with discs on which hammers are attached in an articulated manner in the outer area. They are structurally similar to horizontal impact crushers . The high centrifugal mass of the rotor enables singlestage shredding of feed pieces with edges up to m in one work step to less than 25 mm. Throughput rates of over 2,000 t / h are achieved.

Construction, Working and Maintenance of Crushers for ...

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by a .

Hammer Wear Resistance of the Impact Crusher Matters

Impact crusher is important among crushing equipments, and its hammer is an important part of impact crusher. How does the hammer get wear? Usually in cement, metallurgy, mining, power and other industries, impact crusher hammer handle will withstand alternating bending stress and impact force, while the hammer is mainly exposed to bear relatively strong force of impact and friction.

Ore plant,Benefiion Machine Manufacturer and supply ...

· Hammer Impact crusher,Hammer Mill,Singlestage Hammer . Operating principle of Hammer Crusher: The motor drives the rotor to rotate the hammer crusher with high speed through the belt, and on the rotor there are a series . used stone crushing .

Professional manufacturing compound crusher | ZY mining

The first and second stages of crushing: This section is broken by the principle of a countercrusher. The machine is driven by a motor through a hydraulic coupling to rotate the rotor at high speed. A hammer head is hung on the rotor disc, and the material is separated by the centrifugal force and impacts the material at a high speed to crush the material for the first time.

Mine crushing sand making equipment for sale

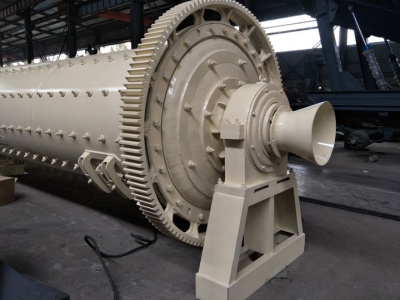

Impact Crusher. Impact Crusher uses impact energy to crush the materials. The rotor rotates at a high speed under the driving force of motor. Ball Mill. Ball mills are used primary for single stage fine grinding. Raymond Mill. Raymond mill is a traditional mill type. contact us.

Gold Ore Processing Solution

The GP (singlecylinder) hydraulic cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines. Eastman singlecylinder hydraulic cone crusher is a highefficiency crusher designed with advanced American technology and the performance of highquality materials in the industry.

single stage hammer crusher design

Singlestage hammer crusher, hammer crusher, hammer mill. Advantages of hammer crusher are as follows: big reduction ration: maximum feeding size is Get Price; Singlestage Hammer Crusher. Singlestage Hammer Crusher is suitable for crushing brittle rock, such as limestone, argillaceous siltstone, shale, gypsum, coal and the mixture of limestone

Design Of Hammer Crushers For Crushing Of Line

Hammer crusher is a singlestage crushing machine that can directly ... singlestage hammer crusher, highefficiency hammer ... sand making production line, ... Read more mobile crusher design

CRUSHING AND GRINDING EQUIPMENT Latest developments in ...

single stage of crushing. Therefore, the Rhodax replaces both secondary and tertiary stages and even the first stage of grinding in most minerals industries in dry or wet processes. The machine first found its place in in dustrial appliions and especially in very abrasives products which require grinding to –1mm (fired clay, corundum ...

draw and label a standard impactor and english hammer mill ...

impactor crusher principle. ... the principle of operation drawing of the machine and all the theory of jaw ... what are the dominant crushing principle of a hammer mill. ... single stage crushing for Vertical mills and Roller Presses Jaw crusher Hammer crusher ...

5 Types of Cone Crushers Comparison

· Contact Now +. Published time:09 October 2019. Cone crusher is one of the most widely used mining equipment. This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one. JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit.

Crusher

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. Primary Crusher

single stage hammer crusher structure diagram

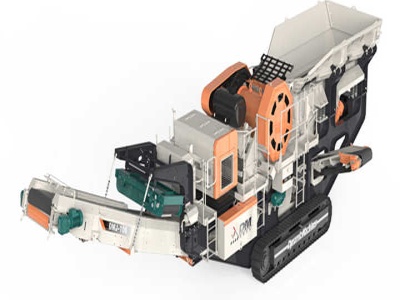

Hammer Crusher. Single Stage Hammer Crusher. Liner Vibrating Screen. Intermittent Ball Mill. Ball Mill. optimizing the structure and function of the machines, pursuing customers'' satisfied design. Intelligent track mounted mobile crushing plant, efficient C series jaw crusher, singlecylinder cone crusher etc are all the result of the . Get Price

Hammer Crusher for Sale|Working Principle, Capacity and ...

Advantages of hammer crusher. The biggest advantage of the hammer crusher is its high crushing rate. And it has strong production capacity, low energy consumption, simple structure, easy operation and maintenance. As China's leading hammer crusher manufacturer, we produce reliable and costeffective crushers. Hammer crusher working principle ...

hammer crusher single stage

Singlestage hammer crusher working principle: In operation, material fed into hammer crusher will be crushed firstly by hammerhead and then by impact plate. Meanwhile, material will crush with each other for the working principle of stone crushing stone.

Working principle of hammer crusher china

Reversible Hammer Crushers Principle. Working Principle hammer crusher Mine Equipments reversible hammer crushers principle Reversible hammer crusher working principle After entering into the crusher the materials are attacked by the high speed hammers and hit to reversible hammer crusher work er Mill Operating Principle 911The Jeffrey Miracle ...

Ore plant,Benefiion Machine Manufacturer and supply ...

· Hammer Impact crusher,Hammer Mill,Singlestage Hammer . Operating principle of Hammer Crusher: The motor drives the rotor to rotate the hammer crusher with high speed through the belt, and on the rotor there are a series . used stone crushing machine in usa. which size of .

how to sense the coal particle size while crushing | Ore ...

· Hammer Impact crusher,Hammer Mill,Singlestage Hammer . Operating principle of Hammer Crusher: The motor drives the rotor to rotate the hammer crusher with high speed through the belt, and on the rotor there are a series . used stone crushing machine in usa. which size of .

Machine Information: Sinounique: Stone Crusher Part III

· Some of the materials that can be destroyed by Hammer Crusher include gypsum, coal, limestone, shards of wood, and so on. The destroyer also features a large range of demolition ratio products and damaged places in lieu of traditional two to threestage disburses. Like some other destroyers, it is also very friendly to repairs and operating costs.

Single stage hammer crusher

Singlestage hammer crusher is used to crush the general brittle ore such as limestone, pelitic siltstone, shale, gypsum and coal. It is also suitable for crus.

Latest Posts

- كسارة فكية من مصر

- آلات لمعالجة خامات الجبس

- كسارة dolimite صغيرة للبيع في المملكة العربية السعودية

- شراء معدات تعدين الذهب في السعودية

- خام الحديد مصنع بيليه في الجزائر

- الشركة المصنعة لآلات تكسير الحجارة

- بيع كسارة الحجر pth

- وحدات طحن الأسمنت في نيبال

- تكلفة مصنع طحن الأسمنت tph

- موردون آلات تكسير المعادن الزرقاء في مصر

- كيف يتم سحق خام الذهب

- الالات كسارة الحجارة بين جاكرتا

- المواصفات الفنية ل صخرة محطم

- معدات محجر التعدين للبيع موريتانيا

- ركام تكسير الفلور

- mobile copper ore mobile rock crusher for sale

- how to make a sieve

- extraction et équipement dans l arctique

- mining machinery portable stone crusher plant price

- south africa copper mining

- coal mining streaming

- fort mill gold hill middle

- mobile crusher for sale at kolhapur

- mqj jaw crusher wear parts suppliers

- plant tanzania plantcrushing

- fabricants de concasseur au canada

- crushing businesses in indonesia

- products and equipment of bonded smelting warehouse

- rock crusher work

- daltile quarry tile unglazed for pizza stone