ball mills not discharging

Ball Mills Market – Global Industry Analysis, Growth ...

Further, ball mills are divided into dry type ball mill and wet type lattice ball, according to different raw materials and discharging methods. These are especially used in mining industry to grind various ores and rocks in metal and nonmetal mines, either wet or dry as per the requirements.

USA

USA US706206A USA USA US A US A US A US 706206 A US706206 A US 706206A US A US A US A US A US A US A Authority US United States Prior art keywords cover drum lining frame rubber Prior art date Legal status (The legal status is an assumption and is not a legal .

Overflow Versus Grate Discharge Ball Mills: An ...

A set of experimental test work has been carried out in a continuous pilot ball mill of X m (diameter X length) at different mill speeds, percent solids and discharge mechanism. The results of study on material flow through a grate discharge tumbling mill verses an overflow tumbling mill are presented to emphasize the effect of ...

Ball mill SM6008A with central discharge for dry material ...

Ball mill SM6008A with central discharge for dry material grinding of medium hardness. Вall mill SM6008А with central discharge and mesh is designed for dry grinding of various ores and construction materials of medium hardness.. The mill is used in construction, ore mining, mining and chemical and other types of industries and operates continuously in various flow diagrams in open or closed ...

USA

USA US210975A USA USA US A US A US A US 210975 A US210975 A US 210975A US A US A US A US A US A US A Authority US United States Prior art keywords trommel discharge annulus mill opening Prior art date Legal status (The legal status is an assumption and is not a .

Difference Between Lattice Ball Mill and Overflow Ball ...

Aug 20, 2020 · Ball mill is the key equipment for crushing materials after crushing. According to the different ways of discharging, the ball mill can be divided into lattice type ball mill and overflow type ball mill. The user should choose according to the technological process and needs. 1. The structural composition is similar.

Ball Mill Discharge Screens Drawing

Ball Mill Trommel Screen For Schmierleitung. A sag mill trommel screen lets you control the true discharge size of your sag mill or the transfer size to the downstream ball mill circuit a well sized trommel should not let rocks pass to the ball mill if they are to be more than say 58 or 16mm in the image case below strangely enough metso is the mill shell liner and discharge grate

Ball Mill Discharge Screen | Crusher Mills, Cone Crusher ...

Screens at the discharge end of a horizontal ball mill are not per se . which employ a screen at the discharge end of the mill to retain the grinding media . Where is the difference between wet and dry ball mill .

Ball Mill

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Articles of Iron or Steel, Forged or Stamped, but not ...

RCA values greater than 1 indie that the state has comparative advantages in Articles of Iron or Steel, Forged or Stamped, but not otherwise Worked (Exc. Balls and Similar Articles. for Mills). On the other hand, high levels of complexity (ECI) are associated with higher levels of income, potential for economic growth, lower income inequality and lower emissions.

Chapter 18. Feed Milling Processes

Oversize particles, not easily broken, drop through the mill and may be recycled or discarded. Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage. Fig. 1 Hammer Mill. Attrition Mills. Attrition mills use the hammermill principle to a certain extent;, shattering by ...

Patterson Industries

The construction of cylinders is the same as other PATTERSON Mills, but sizes are limited in steel ball models to 3'6" x 4'0" and in lined mills to 4'0" x 5'0". PATTERSON D ry Discharge Housings PATTERSON Mills equipped with these Dry Discharge Housings for dry grinding, provide a virtually dustfree operation.

Ball mills for various appliions | Gebr. Pfeiffer

ground product. 1. Mahlkörper. 2. adjustable discharge slots. Activate the markers for further information. Working principle. Fed into the mill through one or both bearing trunnions, the material is ground by impact and friction from the balls. The ground product is discharged from the mill through discharge slots provided in the mill tube ...

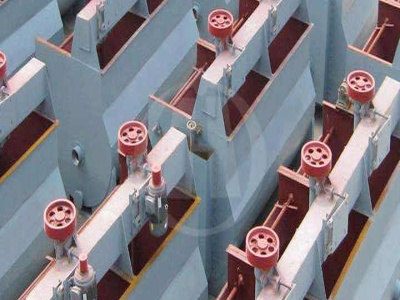

Mill Lining Systems | FluidHandling

Trelleborg has been providing mill lining systems since 1920. The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption. Full lining kits are designed and supplied including Lifter bars, shell plates, pulp lifters, fasteners and discharge grates.

5 Ways To Improve Grinding Efficiency Of Ball Mills

Dec 26, 2017 · Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed. Ball mills with different length to diameter ratios for a particular power rating will produce different material retention times.

Ball Mill for Sale | Grinding Machine

Ball mill is the key equipment for grinding materials. those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc.. JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being ...

Latest Posts

- الشركة المصنعة لويانغ كسارة مخروطية السعودية

- 120 آلة تكسير الفحم tph ومطحنة

- تكنولوجيا الكرة الصغيرة لغرامات خام الحديد

- قائمة مشاريع محطة معالجة الفحم

- معدات مصانع الرمال المصرية

- الرأسي الجا الفحم مطحنة رسم CAD

- الكرة مطحنة عمليات تعدين الذهب

- كسارة فكية 130tph وعملية تكسير الحجارة

- كسارة الحجارة 150 tph الرمال محجر الحجر

- مطحنة نهاية الكرة لمطحنة النحاس الصين

- تنسيق اتفاقية شراء القطارات

- لوحة تأثير لكسارة المطرقة

- تاجر سيور ناقلة في الجزائر

- للبيع مصنع استخلاص الفوسفات

- تستخدم كسارة فكية خام الحديد مزود في السودان

- layar rotary batu crusher di karnataka pasir membuat batu quarry

- quartz sand making machines

- approximately price of stone crusher from nigeria

- price trend vibrating feeder

- jenis penghancur limbah

- cost of ore mining machiner plant

- what is the life cycle of a mine ore

- air density separator for iron ore beneficiation

- capital needed india

- dust collectors for mining

- de broyage de clinker polymérisation

- wheelchair seat air cushion for prevent the bedsores

- how to set crushed lime sand

- comment construire votre propre ballons mills

- sand washing machine used in stone production line