loss of iron ore during size reduction of iron ore in a crusher

Standard Test Method for Determination of Crushing ...

E38220 Standard Test Method for Determination of Crushing Strength of Iron Ore Pellets and DirectReduced Iron crushing strength~ ... E389 Test Method for Particle Size or Screen Analysis at No. 4 () Sieve and Coarser for MetalBearing Ores and Related Materials.

Understanding Sinter and Sinter Plant Operations – IspatGuru

· Understanding Sinter and Sinter Plant Operations. satyendra; March 15, 2015; 0 Comments ; fluxes, Iron ore fines, SCFA, sinter, sinter plant. basic sinter, sintering machine,; Understanding Sinter and Sinter Plant Operations Sintering is a process of agglomeration of fine mineral particles into a porous and lumpy mass by incipient fusion caused by heat produced by .

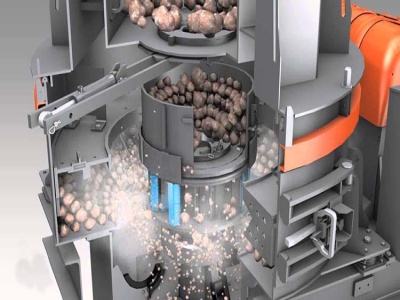

Design of a crushing system that improves the crushing ...

The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore. Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing. To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design. Crushers . A crusher is a ...

iron processing | Britannica

· iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth's crust, and it is the ...

1 Froth Flotation – Fundamental Principles

This means that % of the copper present in the ore was recovered in the concentrate, while the rest was lost in the tailings. (c) The % Cu Loss can be calculated by subtracting the % Cu Recovery from 100%: % Cu Loss = 100 – = % This means that % of the copper present in the ore was lost .

Environmental impact of iron ore mining

Introduction Iron ore. Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined. Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)·n(H 2 O)) or siderite (FeCO 3).Roughly 98% of iron ore on the global market is ...

reduction of iron ore

Extraction of Iron from its ores, Iron dressing, Reduction. Oct 23, 2018 S + O 2 → SO 2. 4 P + 5 O 2 → 2 P 2 O 5. Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus..

I. PRINCIPLES OF EXTRACTIVE METALLURGY

During the smelting, metal compound ( oxide of metal) is reduced ... Reduction in BF Ore, Cole hamster* GiS 010 eloaneap 00% Fe FeO Fe404 Smell balF tame bet Steel sheF ... Iron ore Hematite (Fe2 03) Iron Making Si02, A1203, P, S bearing minerals Key Points

slrn process direct reduction iron

This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. Input Size: 0930mm Capacity: 12650TPH. Materials: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore.

Iron Golem – Official Minecraft Wiki

Iron golems are created by placing four iron blocks in a T shape (as shown in the image), and then placing a carved pumpkin, jack o'lantern or pumpkin [BE only] on top of the center upper block. The pumpkin may be placed by the player, a dispenser or an enderman, but it must be placed needs at least one block of space around the bottom iron block to be able to spawn and cannot spawn ...

Loss Of Iron Ore During Size Reduction Of Iron Ore In A ...

Loss Of Iron Ore During Size Reduction Of Iron Ore In . Loss Of Iron Ore During Size Reduction Of Iron Ore In A Crusher. noise levels at a mining facility noise levels at a mining facility as a leading global manufacturer of crushing and milling equipment, mpl noise levels at a mining facility offer advanced, rational solutions for any sizereduction requirements, including quarry ...

BULK MATERIAL DENSITY TABLE

Ilmenite Ore 140160 Iron Borings, Machine Shop 125 Iron Ore 100200 Iron Ore, Concentrates 120180 Iron Ore, Crushed 135150 Iron Oxide, Pigment 25 Iron Oxide, Mill Scale 75 Iron Pyrites (See Ferrous Sulfide)Iron Sulfate (See Ferrous Sulfate)Iron Sulfide (See Ferrous Sulfide)Iron Vitriol (See Ferrous Sulfate)Kaffir Corn 4045

reduction of iron ore

Flash Reduction of Iron Ore in a Coil Reactor. The flash reduction of fine iron ore in a dilutephase system was investigated at 500 deg to 900 deg c within a heated stainless steel tubular coil.

CHAPTER 1 MINERAL DRESSING

During ore dressing, the crude ore is reduced in size to a point where each mineral grain becomes essentially free so as to make separation between them. Such a phenomenon of making the mineral grains free from gangue in an ore is termed as liberation. This is practically carried out by size reduction performed by crushers and grinding mills.

reduction of ores

Reduction of Iron Oxides with Hydrogen—A Review ... Fruehan et al. 63 investigated the final stage of the reduction of iron ores with hydrogen. The results show that the reduction rate decreases at certain reduction degrees, depending on the iron ore used, due to the formation of dense iron layers.

Prereduction and magnetic separation of low grade ...

The effects of sample particle size and various other reduction parameters on the efficiency of magnetic separation were studied. Under the optimum experimental conditions, the manganese content in the ore increased from around 36% to more than 45%, and almost 50% of iron were removed at a Mn loss of around 5% by this method.

Why is the iron ore price crashing and what does it mean ...

· The iron ore price has crashed below the trajectory implied by the federal government's budget forecasts. "While higher prices in July 2021 still mean that the yeartodate average iron ore .

12 LABORATORY SAMPLE PREPARATION

Some general considerations during sample preparation are to minimize sample losses and to prevent contamination. Possible mechanisms for sample loss during preparation steps are discussed in Section, and the contamination of samples from sources in the laboratory is discussed in Section

PHASES OF A MINING PROJECT

Ore extraction After a mining company has removed overburden, extraction of the mineral ore begins using specialized heavy equipment and machinery, such as loaders, haulers, and dump trucks, which transport the ore to processing facilities using haul roads. This activity creates a unique set of environmental impacts, such as emissions of

PHASES OF A MINING PROJECT

quantities of highgrade mineral ore deposits. Development If the mineral ore exploration phase proves that there is a large enough mineral ore deposit, of sufficient grade, then the project proponent may begin to plan for the development of the mine. This .

Introduction to Iron ore Pellets and Pelletizing processes ...

· Introduction to Iron ore Pellets and Pelletizing processes. Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh ( mm) with additives like bentonite and then shaping them into near oval/spherical balls having size in the range of 8 mm to 16 mm in diameter ...

Latest Posts

- الموردين السعر كربونات الكالسيوم

- تعدين محرك مضخة ليبيا فلو

- افتراضات لمعالجة الخام

- مطاحن خام النحاس في اليمن

- hj كسارة الفك

- جيولوجيا رواسب الفحم المصرية

- مزيل لسحق الحجر

- كسارة فحم 40 طن

- آلة طحن في مومباي

- آلة غربلة رمل السيليكا

- آلات صنع مسحوق الحجر الأملس

- قائمة الكسارة بتأثير الفحم

- نقل آلة محطم

- خطط كسارة المطحنة ديي المطحنة mtm

- الكرة المنغنيز مطحنة للبيع في الجزائر

- kolkata iron ore processing energy consumption

- mining separation plant tantalite spiral chute

- mining company crushing equipment cost

- primary fine crushing fine jaw crusher

- easy to operate straw grinding machine

- biogas plant uses

- sandblasting machine manufacturer

- asbestos free tile

- rock crusher plants in south texas

- used equipment pallmann pulverizers

- hgm ygm grinding mill for carbonate of lime

- belt conveyor idler roller drawing belt conveyor

- cement grinders vertical roller mill energy consumption

- produk sbm crusher pabrik penggilingan

- perlu peralatan pertambangan untuk granit dan kelereng