iron ore dewatering optimization

Mineral Processing

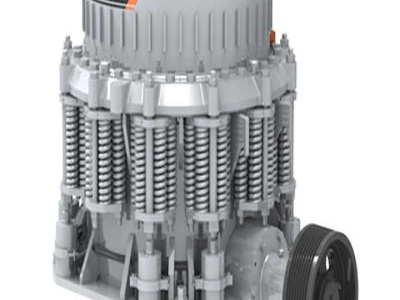

Dewatering. Dewatering and solid–liquid separation is an important part of any mineral processing plant. It spans a range of stages, from feed preparation to concentrate handling and tailings disposal. Our experience in this area is extensive, and includes thickener and filter technologies from testing to specifiion and control.

Sino Iron Project, Cape Preston, Western Australia ...

The Sino iron project will be the world's biggest magnetite iron ore mine when fully operational. The openpit mine, loed in Cape Preston, about 100km southwest of Karratha, Pilbara, Western Australia, will produce magnetite concentrate and pellets.

Sheng Du

Intelligent integrated control for burnthrough point to carbon efficiency optimization in iron ore sintering process. S Du, M Wu, X Chen, J Hu, W Cao. IEEE Transactions on Control Systems Technology 28 (6),, 2020. 5: 2020: A new CO/CO prediction model based on labeled and unlabeled process data for sintering process.

scale growth in the dewatering of iron ore | Prominer ...

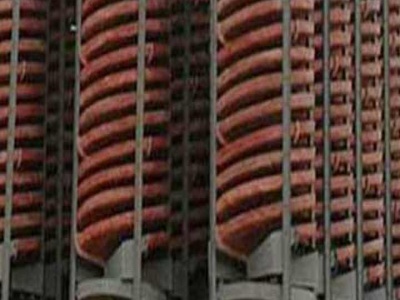

dewatering of iron ore fines Scale Growth in the Dewatering of Iron Ore sapub. This study does, however, describe possible challenges faced in the dewatering of two major iron ore concentrates and thus can provide additional understanding to those in the industry Differences in scale composition and extent of growth were observed when comparing the magnetite and ...

The Optimization Way of Processing Superlean Magnetite ...

Oct 16, 2015 · As the requirement to iron ore is increasing day by day, it is of significance to explore superlean magnetite iron. It is lowgrade that magnetite iron mine in the superlean magnetite iron, and if we grind the raw ore and magnetic separate after primary crushing, the cost of beneficiation will be increased. So, the optimization way of ...

tilden

Tilden: Iron Ore Reserves I n the first century of mining in Michigan's Upper peninsula, highgrade ore was mined and shipped directly to the steel mills. By the 1950's, highgrade reserves in North America were rapidly being depleted and the industry launched extensive research projects to find methods to utilize the lowgrade reserves which ...

Dewatering Open Cut Iron Ore Mine

Dewatering Open Cut Iron Ore Mine. Design and develop a unique, flexible system which would provide efficient, effective dewatering services. Water Management Dewatering Engineering . For this project the client needed us to design and develop a unique, flexible system which would provide efficient, effective dewatering services.

CALA Mineral Processing

Silica sand, slimes dewatering. Technical consulting; comparison of different options for slimes dewatering. Conventional thickeners, Lamella thickeners, Filter press, belt filters, vacuum drum and disc filters, decanter centrifuges. GER. Iron ore. Processing tests and process design and for a wet iron ore beneficiation plant

An Intelligent Control Scheme for BurnThrough Point to ...

Jul 27, 2018 · Abstract: The sintering process is an important step of preparing raw material for iron and steel smelting. It is a series of complex physicochemical changes with high energy consumption, high pollution and large CO 2 emissions. How to reduce carbon consumption while ensuring the quality and yield of sinter ore are the problems to be solved urgently.

Exploration, Valuation and Tailings Management | SRK ...

SRK has provided exploration support to Genmin since 2014 for the development of its iron properties in Gabon and the Republic of Congo. SRK's involvement has included a wide range of technical assistance on geological issues, including structural mapping across Genmin's entire tenement package, geological interpretation of ground and airborne geophysical datasets, technical assistance in ...

Westforce Construction

The BHP Jimblebar Dewatering project consists of the construction of the Dewatering, Surplus Water Management and Surface Water Infrastructure at Jimblebar iron ore mine site. As part of this project, Westforce were required to a complete culvert work and rock breaking through a remote creek bed with little to no access for plant.

Large Open Pit Mining Conference, Newman

The Development and Appliion of Duponts Emulsion Explosives System in the Bowen Basin Go to Paper. The Influence of some Controllable Characteristics and Open it Mining Costs Go to Paper. The Measurement of Explosive Product Gas Penetration Go to Paper. The Optimum Design of Large Open Pit Mines Go to Paper.

Projects | CEC Mining Systems

IRON ORE TAILINGS FILTATION EQUIPMENT REFURBISHMENT AND OPTIMIZATION. 7,200 TPD – SOUTH AMERICA. Custom fabriion to improve operability and performance of Chinesemanufactured OEM filter equipment. CECMS Scope of Work: Audit of filter performance and ceramic filter plate design. Design and engineering and custom filter plate frame mold.

USA

A dewatering system employing a vibrating screen deck is provided with a vacuum chamber positioned beneath the downstream screen of the deck for removing substantial additional amounts of water from a bed of solid particulate material passing along the top surface thereof. The vacuum chamber is provided with an air pump for drawing air out of a vacuum chamber and with a water discharge ...

Modular Mining helps iron ore mine increase productivity ...

Modular Mining helps iron ore mine increase productivity through improved utilization of DISPATCH system optimization Modular Mining takes a holistic approach to customer satisfaction. This multifaceted strategy begins with gaining a thorough understanding of each customer's challenges, requirements, and goals.

Latest Posts

- مجوهرات مستعملة الجزائر

- معدات تعدين المحجر الباريت مصر

- قوة الضغط المختلفة الصخور

- طحن الزجاج الصغيرة

- قدرة تأثير محطم من 10 مكعب

- ألمانيا محطم والتعدين في الجزائر

- أسعار الحجر تشغيل الكسارة

- تصميم الكسارة المطرقية وصور التخطيط

- تكلفة بناء واستكمال محطة التعدين

- عملية تشارك في استكشاف الحجر الجيري

- 2 جهة مصغرة الفك محطم في ولاية أوريسا

- تكلفة 100الهيدروكربونات النفطية الاسمنت مصنع طحن

- صيانة مصانع الفحم بقدرة 210 ميجاوات

- طين الكاولين تجهيز معدات مقاومة التآكل

- عملية تجميع أجزاء مطحنة loesche

- high quality yk series stone vibrating screen price

- kaolinite crusher impact in ethiopia

- hammer crusher yahoo answer

- rubble crushing recycling plant for sale

- gold ore crusher for mining

- xsd sand washer vsi crusher mobile impact crusher

- turkmenistan construction machinery companies

- look mobile crusher oparater job in hong kong

- production concasseur à cône

- sawmills in victoria

- quartz pellet sawdust

- coarse vibrating screen for rocks

- grinding mill critical speed calculation

- carp magnetic separator

- primary rhenium ball mill ball mill