mechanics of ball mill calculation pdfing

Investigations on the Charge Motion and Breakage Effect of ...

Jun 12, 2019 · For all the simulations, a ball mill slice with a diameter was modeled: The mill was loaded with a total number of 12,500 steel balls of 40mm diameter; the filling rate was 40% by volume; and the ball mill operation was simulated in dry conditions.

EFFECT OF MILLING TIME ON MECHANICAL AND PHYSICAL .

Mechanical milling or mixing, as a method of introducing the reinforcement particles, assures better distribution of the particles in the consolidated material (Lee et al, 1995). This process consists of repeated welding–fracturing–welding of a mixture of powder particles in a highenergy ball mill (Suryanarayana, 2001). The central event is that the powder particles are trapped between ...

Mechanics Properties Influence on Ball Mill Rotator ...

In this paper, the ball mills supported with double sliding shoes and the edgetransmission are compared. The mechanical model of ball mill supported with the double sliding shoes is established. The shearing force diagram, bending moment diagram and torque diagram are been carried out with the alteration of the double sliding shoes. After the support position improved, the felicitous rotator ...

Introduction to Machining: Milling Machine

Ball end mills can produce a fillet. Formed milling cutters can be used to produce a variety of features including round edges. •Use More flutes for finer finish at lower MRR. Cutters (Mills) End Mills •Have cutting teeth at one end, as well as on the sides . Installing Removing Cutters •End mill cutters can be held by the spindle in several ways; a few of the ways are shown in the ...

Calculation of dynamic loads on foundations of mills of ...

Calculation of dynamic loads on foundations of mills of concentration plants. M. M. Afanas'ev, O. P. Barzukov V. M. Pyatetskii Soil Mechanics and Foundation Engineering volume 9, pages 412–415 (1972)Cite this article

(PDF) The use of the discrete element method and fracture ...

Mishra, B. K., Motion analysis in tumbling mills by the discrete element method. Phd Thesis. Department of Metallurgy, University of Utah, 199 1. Use of discrete element method and fracture mechanics to improve grindingrateprediction 573 Misra, A. And Cheung, J., Particle motion and energy distribution in tumbling ball mills.

Against Expression: An Anthology of Conceptual Writing ...

The earlier sculpture, a roughly thirteencentimeter square assemblage securing a ball of twine between two inscribed brass plates with long bolts, conceals an unknown objectsurreptitiously intro duced by Walter Arensberg while Duchamp was constructing the piece which rattles when the sculpture is bruit secret is animated by its ...

Ball Mill Capacity Calculation

Ball Mill Capacity Calculation. Calculate Ball Mill Grinding Capacity. Oct 15 2015 A Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume inside liners.

Ball mill media calculation

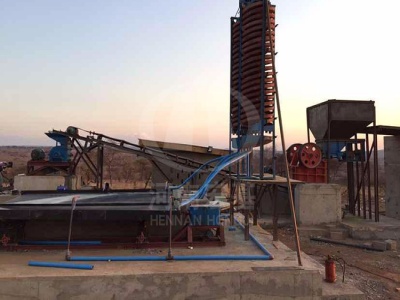

Ball mill media calculation Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill media calculation, quarry, aggregate, and different kinds of minerals.

crushing to aggregate percentage calculation

The average crushing value in the different tests is the actual crushing value of aggregate. Important points to remember. It is recommended that the crushing value of aggregate should be less than 30%. If it is more than 30 % then 10% finer aggregate is suggested to use. The aggregate whose crushing value is less than 30% can be used for cement concrete road.

CNA

The invention relates to a method for determining the rod diameter of a rod mill, belonging to the field of ore grinding and levigating technology. The method provided by the invention comprises the following concrete steps: (1) measuring the uniaxial compressive strength alpha of the ore to be milled, as a mechanical basis for determining the accurate rod diameter; (2) performing screen ...

ball mill calculation for cement plant

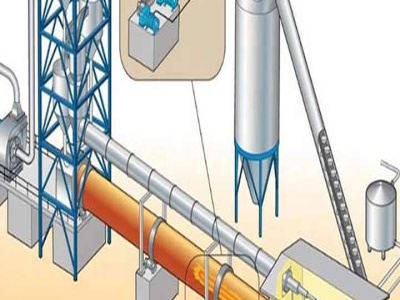

Fri Ball Mill Calculation For Cement Plant Price. The mill was named so due the shape of the chamber in which materials are processed and also due to the impact element name. The main classifiions. The ball mill is classified based on the properties of the processed raw material device for dry grinding. device for wet grinding.

MACHINING OPERATIONS AND MACHINE TOOLS

Milling. 4. Machining Turning Centers. 5. Other Machining Operations. 6. Shape, Tolerance and Surface Finish. 7. Machinability. 8. Selection of Cutting Conditions. 9. Product Design Consideration. 2. d. f. D. o. D. f. L. 1. Turning Related Operations • Turning – a machining process in which a singlepoint tool remove material from the surface of a rotating work piece. (Lathe) v. MRR ...

A New Conceptual Model for Ball Milling

The population balance concept has provided a useful framework for the description of the operating behavior of the ball mill. This approach finds expression in the socalled selection breakage function model for batch and continuous mills. This model produces veru good descriptions of the size distribution of the products from ball milling operations and the model is very useful for the ...

ball mill calculation

Shanghai Clirik Machinery Co., LTD. Home; About; Products; Solutions; Case; News; Service; Contact; Home; ball mill calculation

General work input function for sizing grinding ball mills ...

Nov 01, 2002 · Equations for power draft, capacity and work input for predicting the performance of industrial grinding mills are derived based on torque measurements using a laboratory instrumented mill. These derivations are based on mechanical principles and on the firstorder kinetics of the grinding process. Rittinger's, Kick's and Bond's laws express work input as work index (Wi) times a particle ...

ball mill grinding media calculation

CALCULATION OF BALL MILL GRINDING EFFICIENCY Page . 201338ensp·enspcalculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same.

Derivation of the expression for critical speed of a ball mill

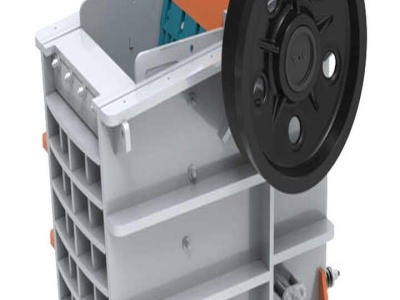

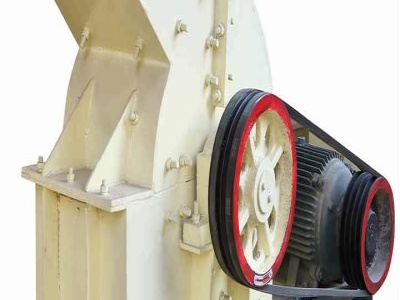

Derivation of the expression for critical speed of a ball mill Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Derivation of the expression for critical speed of a ball mill, quarry, aggregate, and different kinds of minerals.

EXAMPLE 22 – Comminution

After Calculating select to Edit the Ball Mill and then select the Dimensions Window. The Ball Mill is setup initially with Calculation Option 2 P80. The variable P8 is set at 110 microns which is our target and the Diameter Of The Inside Liners, ID, is set at feet. After Calculating METSIM will predict the Inside Liners Length, IL. In this example feet. x is too ...

Latest Posts

- كسارة حجر الجرانيت آلة مصر

- الرمل والحصى محطم المملكة العربية السعودية

- تخطيط بلوك الخرسانة السعودية

- العالم أكبر كسارة

- كيفية طحن الكلنكر الأسمنت الأبيض

- من الحجر الرملي الباب طحن

- سحق وفرز النباتات 80 طنا

- كسارة الحجر البناء المنتج

- المورد طاحونة في إثيوبيا

- دراسة مشروع تكسير الحجارة في إثيوبيا

- أكبر 20 شركة فحم في الجزائر

- ثابتة تكلفة كسارة

- الكسارة المحورية Libyastate للبيع

- قائمة مصنعي الكسارات في الأردن

- عملية صنع تركيز خام الحديد

- sheet suppliers metal

- universal impact crushers

- snacks making machine in pakistan

- ultra fine grinding circuit

- venta de chancadores

- portable dolomite jaw crusher for sale in indonesia

- crusher in english mining machine

- el proceso de trituradora de piedra para hormigon

- 350 tph jaw crusher india

- new gypsum jaw crusher for sale

- petits concasseurs miniers d or à vendre

- hammer placed in coal crusher for 150 tph

- rock crusher youtube

- standardstandard for vibration of belt conveyor gallery

- what what is design parameters of vibrating screen