cement coal 150tph grinding process

coal 150tph mill working principle bowl

PE series jaw crusher is usually used as primary crusher in quarry production lines,, Hi! Glad you can click and enter our website! [email protected] Home Products Solutions About Us Contact. News Center. home; Coal 150Tph Mill Working Principle; coal 150tph mill working principle bowl. working principle of a make cone crusheHomepage Mining Other working principle of a make cone crushe bowl ...

Anjani Portland Cement Limited

Coal Crushing and Grinding Our Company procures coal from indigenous sources. In addition we also use coal that is imported from Australia, Indonesia, and South Africa. They are then blended together to achieve a uniform heat value. The coal mixture is then crushed and ground in a ball mill up to 75 microns in size and stored in fine coal hoppers.

Coal 150Tph Processing Machinery

Coal 150Tph Screening Machines In India. coal 150tph grinding equipment manufacture to Osborn Screens Osborn has the largest range of mining screens availe in the marketUsed extensively in the coal and diamond processing industry the Osborn Multi Slope Type Screen has the capability of handling wet and sticky materials

Fives | Cement Minerals

Jun 22, 2021 · Fives designs, supplies, delivers and installs core process equipment and complete plants for the Cement Minerals industry. From initial project definition to plant commissioning, we provide tailormade solutions to meet your objectives, and optimize your plant's performance.. Fives' technologies are designed to maximize energy efficiency and reduce the environmental footprint of .

Cement Clinker Grinding Machine Plant 100 Tpd

cement clinker grinding equipment plant 100 tpd. Cement Clinker Grinding Plant Unit Rock Crusher Equipment Grinding Mill. grinding mills vary from coarse grinding, medium grinding to micro fine Mill(Grinder Mill)is widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding.

cement factory process interview questions and answers ...

Apr 29, 2013 · » Coal Crushing Grinding Production Line; cement factory process interview questions and answers. Posted at: April 29, 2013 [ ... » 150TPH 200TPH Crusher Plant » 250TPH 300TPH Crusher Plant » 350TPH 400TPH Crusher Plant ... question and answer for cement grinding process .

Emergency inerting systems for coalgrinding appliions

· In the cement industry, this has relevance to coalgrinding systems. Here, Achim Rott from Yara Industrial GmbH explains the different types of inerting systems that can be used to prevent such explosions in the cement industry. To have an explosion there needs to be oxygen (O 2), a fuel source and an ignition source in the same place at the same time. In the case of coalgrinding or .

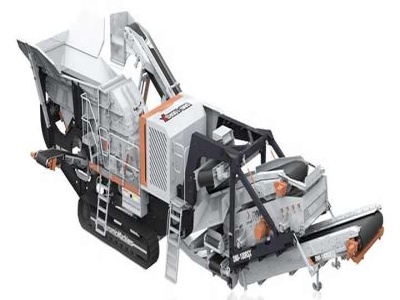

china 150tph stone crusherpgrind

china 150tph stone crusherpgrind. China Manufacturer Crawler Type Mobile Concrete Crushing Plant Movable 150tph Aggregate Quarry Rock River Stone Crushing Plant Find Complete Details about China Manufacturer Crawler Type Mobile Concrete Crushing Plant Movable 150tph Aggregate Quarry Rock River Stone Crushing PlantStone Crushing PlantMobile Crushing PlantCrushing Plant from Crusher .

Ball Mill

Ball Mill Introduction: Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefiion, construction materials, chemical industry, etc, The ball mill is a horizontal rotating device transmitted by the outer gear.

Cement Properties,Composition,Manufacturing and Hydration ...

Aug 23, 2017 · Cement and Hydration of Cement. The dry process is more economical compared to the dry process, because the total consumption of the coal for the burning process is only 100kg, whereas the coal consumption in the wet process is 350kg. In the dry process of cement, the raw materials are crushed in the absence of water and put them into grinding ...

Flow Chart Manufacturing Process In Automobile Industry Ppt

New dryprocess cement plant is composed of raw materials crushing equipment, grinding equipment, cement grinding equipment, cement rotary kiln and other equipment. ... and coking is the largest segment of the industry representing 29 of Russias overall transportation volumes in 2017 coal grinding. ... Coal 150Tph Used In Coal 150Tph Pulverizer ...

coal crusher plant 150tph

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarly.

coal crusher price table grinding limestone rock

mobile concrete crusher process 1 Stone Crusher For Sale ... mobile concrete crusher process 1 ... flow chart for crushing plant sale price in peru china supplier mining machine ore cone crusher 5 ... crusher prices grinding mill china stone crushers profits case study limestone sorting limestone ... machine price hobby New type 100t rock jaw crusher melbourne what are coal crushing...

Cement Industry and Audit Presentation

Jan 17, 2013 · Cement Input/Output OverviewRaw Process Product/OutputMaterial/Input • Mining Clinker/RMC• Limestone/Soil • Crushing OPC (Non• Gypsum/Slag • Grinding Slag)• Coal • Blending PPC• Pet coke • PreHeating PSC/PBFSC• HSD Oil • Clilnkerization GGBS• Fly Ash • Cement Grinding Power Misc. Exp. Freight • Electric ...

Using Coal Ash in Highway Construction: A Guide to ...

(The use of the term "coal combustion products" in this docu ment does not change the legal definition of solid waste as defined in RCRA 42 6903(27).) Concrete: A construction material consisting primarily of aggregates, Portland cement, and water. Certain coal ashes can be used as a replacement for a portion of the Portland cement.

150TPH Russia Opencast Coal Mine in Russia

About us. Founded in 1987, Liming Crushing Company is mainly engaged in the RD and manufacturing of largescale equipment required for construction, energy, transportation and other national infrastructure construction projects, as well as providing technical solutions and supporting products.

Cement

Cement making is a power consuming business. Pyro string and downcomer are perfect spots to lower emissions and save energy with our flow meters. Even efficient vertical roller mills (VRM) offer an optimization potential by better and more reliable raw gas flow measurement. Hot and most dusty gases from rotary kiln, preheater tower and clinker ...

Portland Cement Manufacturing Industry: National Emission ...

Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln. The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materials.

Cement

Dec 04, 2019 · The direct CO2 intensity of cement production increased % per year during 201418. To get on track with the SDS, a % annual decline is necessary to 2030. Sharper focus is needed in two key areas: reducing the clinkertocement ratio (including through greater uptake of blended cements) and deploying innovative technologies (including CCUS).

Difference Between Wet And Dry Process Of Cement ...

Wet process. 1 Mixing of Raw materials in wash mill with 35 to 50% water. 2 Materials exiting the mill are called "slurry" and have flowability characteristics. 3 Size of the kiln needed for the manufacturing of cement is bigger. 4 Raw material can be mixed easily, so .

Cement

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

Latest Posts

- الجاذبية إثراء الهيماتيت خام

- المصنعة لآلات الطحن

- تستخدم الكسارات الخرسانية المدمجة للبيع

- طاحونة الحجر في عنوان الصين

- سعر كسارة الحجر التمساح

- مصنع الفحم في أداء محطة توليد الكهرباء

- سحق الثانوي والعالي الأولية

- مخروط محطم تفكيك

- الحجر الجيري المحاجر في ميانمار

- سحق غبار الحجر الصخري المسحوق

- محطم المعدنية الناقل

- آلة مطحنة الكرة أداء

- كسارات الخراطة المعدنية الدائري المتداول

- آلات تعدين الذهب في السعودية

- قفازات القفازات المطاطية المصنعين

- guiemas bijih crusher cina

- iso certificated gold ore washing rotary trommel scrubber

- used iron ore mining equipment plantand machinery

- foss digestor 2006 service manual

- world bank s gold mining policies

- blasting techniques for better fragmentation of stone

- pabrik emas msi tv5 dijual

- sand crusher plant in rajkot

- and crusher in albania

- grinding mill capacity 3000kgs

- stamp mill suppliers in harare

- mobile gold recovery plant for sale

- types of pulverizer mill in power plants

- quarry resources in nz

- bitumen pressure distributor truck mounted