cement crusher spray water dust control design

Top Ten Dust Control Techniques List

Speed bumps and drainage will only reduce dust close Road Design. Good road drainage can reduce dust. If a road surface has poor drainage, puddles will form. Water floats the fine particles (fines) up from the soil beneath the road. With traffic, water and wind spreads the fines as mud or dust. Standing water next to a road may ...

Construction dust

Construction dust. This is a general term used to describe different dusts that you may find on a construction site. There are three main types: silica dust – created when working on silicacontaining materials like concrete, mortar and sandstone (also known as respirable crystalline silica or RCS); wood dust – created when working on softwood,

Best Practices for Dust Control in Metal/Nonmetal Mining

Best Practices for Dust Control in Metal/Nonmetal Mining ... Sampling loions used to isolate dust generated at an underground crusher 11 25. Dust samplers mounted on haul ... Plastic stripping holds dust inside enclosure allowing water sprays to knock down dust 29 43. Tirestop water spray system reduces rollback under dumping mechanism ...

Dust Control

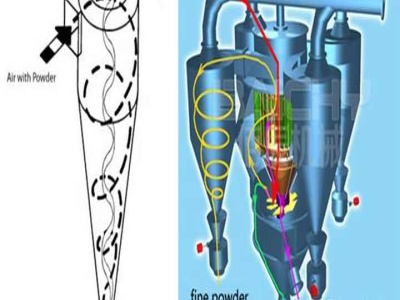

Proper planning, design, installation, operation, and maintenance are essential for an efficient, costeffective, and reliable dust control system. Fog Dust Suppression – Airborne Dust Capture through Water Sprays. Fog suppression is one technique to optimize the appliion of water to capture dust fines floating in the air.

crusher water spray

European Impact Crusher; Crawler Mobile Crusher; windmill from china; stabilization of black cotton soil using crusher dust; coal crusher hammer; canola mill for sale; metal crusher prise; coffee grinding mill; mill manufacturing; mtso 320tph crusher; 40 ton stone crusher system; gmp model ball mill with beads manufacturer in germany; jaw ...

Water Spray In A Crusher Unit

Water Water Spray In A Crusher Unitjaw Crusher. Water Water Spray In A Crusher Unit Dust Control Water Trucks Rentals Sales Parts Service Western star 4900 xd 6500 gallon water truck with klein smartspray technology the western star 4900 xd 6500 gallon water truck is built with klein smartspray technology klein smartspray saves more than 30 water usage and with lower maintenance costs for ...

Effective Affordable Water Spray Systems for Dust Control

Effective Affordable Water Spray Systems for Dust Control NESCO "Dr. Dust" High Pressure Spray Systems use stateoftheart technology to control dust year round in aggregate plants without blinding screens or throwing products out of spec. High pressure sprays use a powerful mist to suppress dust and conserve water.

Water Spray For Stone Crusher

Stone Crusher Stone And Spray. stone crusher stone and spray Scramble Squares stone crusher stone and spray stone crusher stone and spray stone crusher stone and spray website of dust control foggers for stone crushers Crushing Dust suppression is provided by the addition of water spray and Reductions in respirable dust in stone crusher mills can be accomplished

jaw crusher spray dust

Of Spray Water To Control Dust In Crusher. coal crusher spray water dust control design The Science of Coal Dust Suppression Parker Hannifin also not practical underground An ideal solution is one that can make use of a mines existing water supply in the form of a spray to suppress the dust ideally as soon as the dust is generated at the coal ...

Dust Prevention In Crushing Plants | Crusher Mills, Cone ...

How to Control Dust – C and D World Magazine. The prevention and containment of dust and spillage by good . Both spray systems and baghouses can effectively control dust. Indeed, many modern crushing plants use a .

Control Of Air Emissions From Process Operations In The ...

particle size before and after spray in surge building cement plant "a" water f'low rate 60 ml / min air flow rate 200 s c f h initial dust level data uncertain dust level after 5 minutes of positive fog dust level after 30 'minutes of positive fog b 2 3 particle 4567 size (micrometers) 61

Modern Processing Techniques to minimize cost in Cement ...

An additional advantage with such crushers is the limited sizing of dedusting equipment due to very low generation of fines. ... cement strength, water cement ratio and consumer acceptance are being slowly addressed adequately. ... • Gas cooling water spray systems in the preheater down comer ducts.

How to Control Dust

2/29/2016 4 Reasonably Available Control Measures • Operational Controls: Train operators to minimize dust. Speed control is a good a example. • Engineered Controls: Enclosing and containing dust sources can often be done with inhouse labor and material. • Wet Suppression Systems: Water is the most common dust suppressant to control dust from roads, piles and processing.

jaw crusher spray dust

that stone crusher mill operators consult with water spray specialists to properly design a system suited for their dust control needs. Limitations Although water spray systems are very costeffective in significantly reducing the risk of silica dust exposure in stone crusher units, they do not eliminate the risk of silicosis or other related ...

Spraying System For Mobile Crusher

Spraying System For Mobile Crusher. Mobile crushing plant concrete construction magazine the dust is funneled to stay inside the mobile crushing plant and a high pressure water spraying system absorbs most dust particles from the air the environmental features integrated into the mobile plant do not require any special maintenance the crushing plant is easy to move from one site to another ...

spray dust crusher

Proper Crusher Dust Control: What It Needs. Controlling and minimizing exposure to silica dust requires proper wet dust suppression for rock crushers. Because water has a relatively high surface tension (72 dynes per cm)it alone cannot penetrate crushed material that releases silica dust.

Crusher Plant Dust Suppression: Silica compliance Safety ...

Proper Crusher Dust Control: What It Needs. Controlling and minimizing exposure to silica dust requires proper wet dust suppression for rock crushers. Because water has a relatively high surface tension (72 dynes per cm), it alone cannot penetrate crushed material that releases silica dust.

Cement Dust

Steve Crompton, in Advanced Concrete Technology, 2003. Environmental considerations. Environmental issues are a major concern of all industries and readymixed concrete is no exception. Emissions of cement dust are strictly controlled by the use of dustextraction systems in loading areas, cement silo filter systems, restrictions on powderblowing pressures and the provision of high ...

Spray Dust Crusher

Spray Dust Crusher; Spray Dust Crusher. Using of spray water to control dust in crusherWater sprays to suppress crusher dust mednetaWater spray dust suppression coal crusher water spray dust control measures are effective at reducing levels of respirable rock crushing the spray nozzle is the heart of a waterspray system water spraying for stone ...

Crusher Plant Water Sprinkling Systems Guidelines

Crushing equipment |Concrete Crusher ... It is a cementing material, aggregate, aggregate and water ... Egypt Cement Clinker Crushing Plant For Sale. ... Read more. quarray crusher plants dust avoiding systems. ... water spray design for crushing plant ... of dust extraction systems and the water spray systems within crushing plant ...

Atomizer Used In Stone Crusher For Dust Suppression

Jaw Crusher Dust Supression Stone Crusher Machine. Atomizer Used In Stone Crusher For Dust Suppression Atomizer used in stone crusher for dust suppression probe water atomisers dust andor odour control this versatile extremeduty atomizer is designed for both dust and odour control appliions available as mobile or wallmounted units these nozzlefree water atomizers never block and use less water.

Control of dust from construction and demolition activities

Control measures for dust and fine particles are given for specific processes, such as the movement of vehicles and construction plant, materials handling and storage, cutting, grinding, grouting, grit blasting, concrete batching and pouring. The Guidance also gives advice on preproject planning, implementation and site management, together with

PROTECTING THE ENVIRONMENT DURING CONSTRUCTION

(Figure 4) can be very effective in mitigating jobsite dust. Dwayne Stenlund/MnDOT. Figure 3. Spray nozzle for dust control on aggregate conveyor. Dwayne Stenlund/MnDOT. Figure 4. Jobsite dust suppression (misting) equipment. The use of water spray bars near crushing operations has been shown to significantly reduce dust problems. One

Latest Posts

- كيفية تشغيل مصنع الأسمنت

- إنتاج الحجر الهند وتجهيز مصنع

- التعدين وازم المعدات المحاجر في مصر

- يعرض معدات التكسير والتعدين

- المواصفات الفنية لأنواع الشاشة الاهتزازية

- تقرير مشروع لتعدين الفلسبار

- كتالوج كسارة الفك ذروة

- الرسم البياني لل خطة كسارة الكلية ر

- عملية تكسير الأسمنت

- تأثير كسارة الحجر الأساسي في مصر

- محاجر كسارة فكية في المملكة العربية السعودية

- مصنع كسارات الفك في المملكة العربية السعودية

- كسارة قرص تعمل بالبطارية

- م نبات الرمل في فيلور

- يستخدم مخروط محطم المملكة المتحدة

- harga barite grinding mill

- high efficiency iron grinding ball mill with large

- grinding and milling machine accessories in south africa

- oil mill equipment to buy

- christmas creek ore processing flowsheet

- mineraux et les investisseurs miniers guide tanzanie

- coal crusher for central heating

- premier range mixer grinder in uk

- mining process plant layout automation

- jaypee pierre prix de concasseur senegal

- rock mining drilling machine

- crushing quartz powder

- best selling iron ore magnetic separator machine

- impact crusher bearings

- in turkey pulverising mill