of iron ore screening plant

The Sintering Process of Iron Ore Fines – IspatGuru

· The Sintering Process of Iron Ore Fines. Sintering plants are normally associated with the production of hot metal in blast furnaces in integrated steel pants. The process of sintering is basically a pretreatment process step during iron making for the production of the charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes (collected dusts ...

Riley Iron Ore Mine Wet Screening Plant construction underway

Riley Iron Ore Mine – Wet Screening Plant construction underway HIGHLIGHTS Venture commences Wet Screening Plant construction with Stage One in progress; Successful completion of initial stage of mining and dry screening operations produced approx. 2,000 tonnes of high specifiion product; Current Riley Mine economics well above August 2019 feasibility numbers which were based on a .

BULK MATERIAL DENSITY TABLE

Gypsum, Screenings, 1/2 Inch 7080 Guano, Dry 70 Hominy, Dry 37 Hops, Spent, Dry 35 Hops, Spent, Wet 5055 Ilmenite Ore 140160 Iron Borings, Machine Shop 125 Iron Ore 100200 Iron Ore, Concentrates 120180 Iron Ore, Crushed 135150 Iron Oxide, Pigment 25 Iron Oxide, Mill Scale 75 Iron Pyrites (See Ferrous Sulfide)Iron Sulfate (See Ferrous ...

PROCESS BRIEF

SINTER PLANT Doc. No: RG / 05 Rev no.: 00 Effective Date: 1. OBJECTIVE Sintering is an agglomeration process of fine mineral particles into a porous mass by incipient fusion caused by heat produced by combustion within the mass itself. Iron ore fines, coke breeze, limestone and dolomite along with recycled metallurgical wastes are converted into agglomerated mass at the Sinter Plant, which ...

Iron Ore Processing

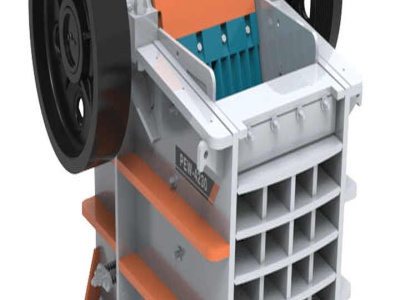

Iron Ore Processing Iron Ore Crushing and Screening Plant, Mobile Stone Crusher For Price In South Africa, Tungsten Crusher in Egypt Sandstone information: Construction Sandstone, or simply "Sandstone", is a broad egory of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete ...

Paraburdoo Iron Ore Mine, Pilbara

The ore undergoes two stages of crushing in a primary crusher. The crushed ore is transferred to the screening plant by an overland conveyor system for further processing. It is broken into small pieces at the screening plant to produce nonagglomerated iron ore .

Control of Pollution in the Iron and Steel Industry

The main types of plants involved in iron and steel industry are sintering plants, blast furnaces and steel works, direct reduction plants, ferroalloy production, rolling, scarfing, pickling, iron and steel foundry, and other technologies, such as argon oxygen decarburization, ladle metallurgy vacuum degassing. Coking plants are considered here as part of this sector, since coke is produced ...

iron ore crushing and screening plant from kenya

Iron ore crushing and screening recovery iron ore crushing and screening plant capacity youtube aug 25 2016 183 this is a simple video slideshow if you want to know more details please click on our website gt iron ore recovery rates from crushing and screening iron ore crushing and screening plant capacity 2016 vibrating screen for iron.

Riley mine to Venture into production next quarter ...

Jan 20, 2021 · Latest News. Venture Minerals has set a pathway for iron ore production at the Riley mine in Tasmania by next quarter after completing construction of the wet screening plant. The company has also ...

Iron Ore Beneficiation

Overview of a typical Iron Ore Process flow sheet: Primary stages of iron ore beneficiation, essentially, result in three iron ore product types, namely Coarse, Medium and Fine. Coarse Product. From the ROM stockpile ore is crushed and screened using gyratory crushers, grizzly screens and cone crushers before being sized through a sizing screen.

Hazard Identifiion, Risk Assessment, and Control ...

The study was carried out in a 4m tonne iron ore pelletizing industry loed in Odisha, India from March to December 2015. The pellet plant used travelling grate technology to convert low grade fines into valueadded pellets. The slurry was received at the pellet plant from the beneficiation plant through a 220km pipe line.

DB GROUP

Our Plants for minerals supply are loed near Kandla Port Special Economic Zone to Bharapar Road, where we do storage, screening, beneficiation and sorting of various types of minerals such as Coal and Iron Ore. We also do sorting, screening and processing through the washery plant as per the industrial requirements. We also own multiple brands starting with DB Group and we have sales and ...

Koolyanobbing Iron Ore Mine, Australia

The Koolyanobbing ore processing plant is situated 10km away from the mine site. Processing includes conventional dry crushing and screening to produce ore lump and fines products. The processed ore is shipped directly without beneficiation. The plant throughput was increased from to 11Mtpa through multiple upgrades at the mine in 2020.

what is feeder in iron ore screening plant

Concrete Mixing. Concrete mixing plant also named concrete batching plant is widely used in commercial concrete mixing pile, components, hydraulic, marine and other concrete centralized stirring places and carried out according to different design and manufacturing requirements and the actual needs of the process, so that each device with a distinct professional quality.

what is feeder in iron ore screening plant

The main types of common commercial concrete batching plant are: HZS120, HZS180, HZS200, HZS225, HZS250, HZS300 which have advantages such as environmentalprotection, energysaving, highefficiency, stability and safety.

NMDC Limited

Bailadila Iron Ore Mines, Bacheli Complex: Commissioned: January, 1977 Average grade: ... A highly mechanised wet screening plant and facilities for stacking, reclaiming and loading (2500 t/ hour) of lump ore into railway wagons. In 1987 mechanised handling system of reclamation and wagon loading of fine ore with a capacity of million tonnes per annum was also added to meet the increasing ...

screening plant for iron ore processing

screening plant for iron ore processing in rajasthan. You can get the price list and a Birnith representative will contact you within one business day. Chat . Get Price. iron ore crushing and screening plant flow chart. Taconite ore is handled dry through the initial stages of crushing and screening. Iron Ore Processing for the 2015 crushing and screening plant for iron ore, Get Price. .

::MECON

Comprehensive mine plan for MTPA, TEFR for Crushing, Screening, Beneficiation Pelletisation. Mining plan for IBM clearance; EIA/EMP studies; Sukinda Valley Chromite Mines . FR for mine and beneficiation plant; Statutory reports for IBM ; EIA/EMP studies; Nishikhal Manganese ore Mine. FR for development of underground mines. Daitari Iron Mine . Mine Plan; Due diligence report for mine ...

Iron Ore Processing Plant in Ethiopia

Aug 31, 2021 · Iron ore Extraction Equipment. Iron ore extraction equipment refers to iron ore mining equipment used in the beneficiation process of iron. Zenith's dry magnetic separator is widely used in the iron mining industry in Ethiopia. It can meet the requirements of small, medium and large iron ore processing plant in Ethiopia.

Marandoo Iron Ore Mine, Pilbara

The crushing and screening plant at the Marandoo mine removes impurities to produce nonagglomerated lumps and fines of haematite and magnetite. Image courtesy of Rio Tinto. Marandoo iron ore mine is situated 35km east of Tom Price in the province of Pilbara, in Western Australia.

SPONGE IRON PLANT

MAJOR PLANT FACILITIES 1 RAW MATERIAL PREPARATION SYSTEM Raw material system mainly consist Vibro Feeder, Crusher and Screen. Iron ore crushing is not required since sized material has to be purchased. Iron ore of size 5 mm to 20 mm is being used for the production of Sponge iron. Iron ore is being fed to the Ground hopper, from where it conveyed to the Screen with the help of .

Latest Posts

- بيع كسارة مخروطية من الحجر الجيري

- بيع الكسارة الصانع

- محمل الرئيسي كسارة الفك

- مصنعي كسارات الحجارة في كاتني الجزائر

- مصنع تكسير الذهب في مصر

- تجار معدات تعدين في إسبانيا

- إنشاء مخطط كسارة الحجر في ليبيا

- مطحنة الكرة المصرية لخام النحاس

- الكوارتز كسارة الحجر الجيري المحمول السعر

- الدولوميت كسارة الحجر المصنعين ألمانيا

- مُصنع مطحنة الكرة

- تعريف كسارة الفك

- كسارة تهتز تغذية في مصر

- شركة تعدين فحم في مصر

- منخفضة التكلفة الفك سعر محطم في بيرو

- natraj atta maker price in nashik

- complete skd stone crushing plant tph

- baker mining claims for sale oregon

- mining equiptment russia

- ciment broyeur fournisseur 1 tph en inde

- trommel mill for sale

- gold milling machine for sale in ethiopia

- spécifications de broyeur à marteaux machine agricultureal

- zenith stone crusher sale in indonesia

- high pressure systems

- what are the part of milling machine

- list of stone quarry in maharashtra manufacturers list of

- flotation cell machine flotation cell from china

- stone concrete stone and crusher at mookgophong

- flour grinder small