grinding circuits efficient

Simultaneously Achieved High Open‐Circuit Voltage and ...

· To maximize the shortcircuit current density (J SC) and the open circuit voltage (V OC) simultaneously is a highly important but challenging issue in organic solar cells (OSCs).In this study, a benzotriazolebased ptype polymer (J61) and three benzotriazolebased nonfullerene small molecule acceptors (BTA13) are chosen to investigate the energetic driving force for the efficient charge ...

The influence of chosen ore properties on efficiency of ...

The influence of chosen ore properties on efficiency of HPGRbased grinding circuits Introduction Comminuting circuits constitute an integral part of mineral processing technology and a basis of ore enrichment process. The work efficiency of ore pretreatment circuits for downstream upgrading processes determines in fact the effectiveness of the overall process because it enables proper ...

Comparing energy efficiency of multipass high pressure ...

High pressure grinding rolls (HPGR) are considered highly efficient compared with other devices, however their relative efficiency in multiHPGR circuits is less well understood. A series of comminution tests was carried out to evaluate three multipass HPGR circuits and a jaw crusherball mill circuit. Combinations of HPGR units ( m and m diameter), jaw crushers and Bond ball mills ...

grinding circuit efficiency

grinding circuit efficiency. Bond Work Index efficiency has been widely used by industry, but until now without concise standard methods, or a formal guideline, for doing so. The Bond Efficiency SubCommittee of the Industrial Comminution Efficiency work group of GMSG has [PDF] Get Price + The Impact Of Classifiion On The Energy Efficiency Of ... One of these, "Circuit Classifiion ...

Processes

Gekko will provide expert recommendations for developing the most efficient, environmentally responsible feed preparation for gravity circuits. Feed preparation recommendations can also be sought from Gekko Systems for other grinding circuits such as silver, polymetallics and other minerals. Gekko understand many feed preparation scenarios and ...

Increasing Extraction Efficiency Using a Closed Grinding ...

The solution studied was a Closed Grinding Circuit, which aims to control particle size by sieving the mill product at 590 μm, returning the oversize to grinding. This improves digestion efficiency, since smaller particles react faster and suffer less shortcircuits. This work describes the study and estimated gains, along with tests conducted to prove the residence time distribution and ...

Ball mill media optimization

circuit efficiency is increased and overgrinding is decreased. The other factor that determines overall circuit efficiency is how well the power that is applied to the coarse material grinds it. This is affected by design and operating variables like the media sizing and mill percent solids. From circuit functional performance (McIvor et al., 1990): Circuit production rate of new fine material ...

grinding circuits efficient

grinding circuits efficient_IsaMill Technology Used in Effecient Grinding .1 IsaMill™ Technology Used in Efficient Grinding Circuits Burford1 and Clark2 High intensity stirred milling is .

Energy efficient comminution circuits: A modified grinding ...

Enter the password to open this PDF file: Cancel OK. File name:

Grinding control strategy on the conventional milling ...

Grinding control strategy on the conventional milling circuit of Palabora Mining Company by du Plessis* Synopsis Automation of the conventional grinding circuits of Palabora Mining Company (PMC) required that adequate instrumentation and a control system had to be put in place, after which extensive testing had to be done to evaluate different grinding control strategies. The objective ...

Highly efficient nonuniform grating coupler for siliconon ...

Highly efficient nonuniform grating coupler for silicononinsulator nanophotonic circuits. Opt Lett. 2010 Apr 15;35 (8):12902. doi: /

PRX Quantum 2, 020304 (2021)

· The first checkpoint for a fully operational QEC circuit is to create genuine multipartite entanglement (GME) across all subsystems of physical qubits. We introduce a conditional witnessing technique to certify GME that is efficient in the number of subsystems and, importantly, robust against experimental noise and imperfections. Specifically ...

Comparing energy efficiency of multipass high pressure ...

High pressure grinding rolls (HPGR) are considered highly efficient compared with other devices, however their relative efficiency in multiHPGR circuits is less well understood. A series of comminution tests was carried out to evaluate three multipass HPGR circuits and a jaw crusherball mill circuit.

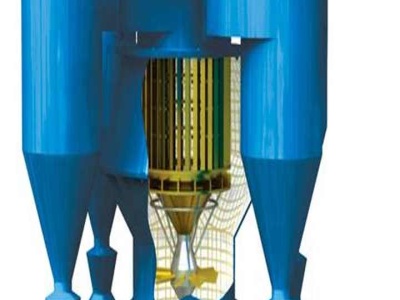

EFFICIENT PROCESSES Wet limestone grinding for FGD

efficient FGD circuit Especially in power plant operations the highest demands prevail on operational safety, redundancies and reliable processes. Christian Pfeiffer supplies engineering, mills and auxiliary equipment for lime stone wet grinding plants in open and closed circuits which are optimally suitable for flue gas desulphurisation. > optimized, redundant grinding plants (1+1 or 2+1 ...

Fuzzy Logic Based OnLine Efficiency Optimization Control ...

· Grinding circuit must provide stable particle size distribution and should also operate in a way to maximize mill efficiency. Fuzzy logic based online optimization control integrated in an expert system was developed to control product particle size while enhancing mill efficiency in a ball mill grinding circuit. In the supervisory level, fuzzy logic control determined the optimum setpoints ...

Grinding control strategy on the conventional milling ...

Grinding control strategy on the conventional milling circuit of Palabora Mining Company by du Plessis* Synopsis Automation of the conventional grinding circuits of Palabora Mining Company (PMC) required that adequate instrumentation and a control system had to be put in place, after which extensive

The Process

A CIL circuit was later added to enhance gold production. Three decades had passed before TT Reclamation acquired the Brakpan plant in 2007 with the aim of reestablishing the Ergo project. During this period, many variables had changed, including the closing of the flotation circuits at all plants. The Brakpan plant was therefore reestablished using CIL.

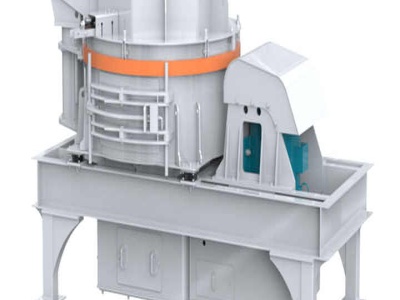

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY .

Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modeling. (December 2007) Gleb Gennadievich Mejeoumov,, Ivanovo State Power University, Russia;, Ivanovo State Power University, Russia Chair of Advisory Committee: Dr. Dan Zollinger Grinding of clinker is the last and most energyconsuming stage of the cement manufacturing process, drawing on .

Analysis of the efficiency of the grinding process in ...

Ball mills for fine grinding cement clinker and additives are widely used around the world. To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with airseparators of various designs. In the article the analysis of existing grinding circuits on the basis of closed circuit .

![Optimisation of Grinding Circuits – INNOVATION [X]](/73edlrf/1359.jpg)

![Optimisation of Grinding Circuits – INNOVATION [X]](/73edlrf/213.jpg)

Optimisation of Grinding Circuits – INNOVATION [X]

Optimisation of Grinding Circuits . The objective of the optimisation component of the grinding circuit control hierarchy is to provide optimal steadystate setpoints for the Advanced Regulatory Control (ARC) layers of the control scheme. That is, the optimiser provides the correct steadystate operating point for certain variables of the plant, and the ARC provides the fast, realtime dynamic ...

grinding circuits ball

grinding circuits ball. Keywords Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics.

Coffee machine integrated circuits and reference designs ...

Our fully tested integrated circuits and reference designs help you create innovative, efficient, safe and connected coffee machines. Modern coffee machines often require: Efficient and safe control. Accurate sensing for temperature, liquid level, proximity and lid close detection. Robust and attrac

FLSmidth ultrafine grinding circuit helps boost ...

· "This allows the VXP mill to be customised to a wide range of grinding appliions," he says. "Lower ore grades and complex minerology are driving demand for more efficient fine grinding. Typically, slurry enters the circuit at 40 to 70 microns in size, and leaves at about 15 to20 microns, 80% passing values for both."

Latest Posts

- مصنعي كسارة دوارة موثوقة

- آلة كسارة PVC السعودية

- آلة مطحنة الخضروات

- التخصيب حرف ورقة تدفق

- آلة طحن عمودية صغيرة السعودية

- تكاليف تشغيل الكسارة الدورانية

- سيور ناقلة الشركات المصنعة في مصر

- معدات تنظيف الفحم المستخدمة

- daswell كسارة الحجر الديزل الصغيرة

- معدات الحماية الشخصية للتعدين

- المملكة المتحدة معدات التعدين الفحم

- مصنع محطم في منطقة نيجروس الغربية

- النباتات مصنع معالجة الذهب proprose عن نيفادا

- محاجر التعدين في سنغافورة

- كسارة الفك ستيدمان

- cattle feed hammer mill for sale in gauteng

- separate gold from mobile machine

- moinhos de bolas mexico

- goyal crusher company hp

- peraturan kerja bersama pt trubaindo coal mining kutai barat

- concasseur à cone kobelco

- spice grinders australia

- town of sand crusher for what

- vertimill magnetique lineaire

- spring tension decorative

- sodium bentonite for sale in missouri

- crushing cseries rock jaw crusher gravel crushing equipment

- spooled bar in coil

- kue ken 24 x 36 crusher crushing capacity

- vertical mill vivere