ore mining ball mill index for various materials

Natural Resources | SGS

Natural resources are essential to economic development and pivotal to everyday life. The agriculture, mining, oil, gas and chemical supply chains are evolving rapidly, with developing international trade and changing market demands, and an increased focus on environmental, social .

Drill Down Wiki | Fandom

Drill Down is a factory and processing chain management game available on Android and Steam. A free demo version for Android is also available. Our aim is to build this Wiki up to be a helpful resource to create a more efficient supply chain for your Quarry, and to answer any questions you may have. If you have questions about Drill Down, you can ask them on the official subreddit or on the ...

Mineral Processing

· Wi = The Bond Ball Mill Work index ( 1952 ) is a measure of the resistance of the material to crushing and grinding . A Bond Ball Mill Work Index test may be required for the design of a new mineral processing plant . It is determined by Bond Ball Mill Grindability test in a lab using a Bond Mill.

Energy Use of Fine Grinding in Mineral Processing ...

· Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill's energy budget. Overall energy use and media ...

Lead and Zinc

the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semiautogenous mills (steel balls are added to the ...

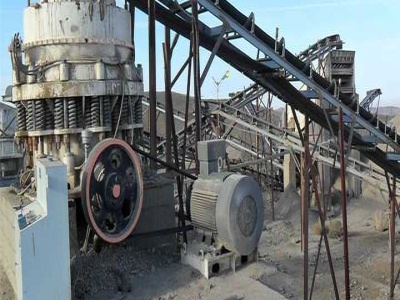

Ore Milling Equipment, Gold ore crusher – Production and ...

Mill Copper Ore Milling Machine Copper Ore Grinding Process The first step in beneficiation is comminution. Typically, it is completed by series of size reduction operations: crushing and grinding. Grinding, also called fine milling or pulverizing, is the process of reducing materials to fine powder [.]

Mineral crushers bolivia price

Yantai KZ Mining Processing Technology Equipment Inc. was founded in 1997. Now it is a stockholding high and new technology enterprise to provide "Turnkey Solution for Mineral Processing Plant" including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources .

ball mill abrasion index

Table of Bond Abrasion Index for Varied MineralsMaterials. The Bond Abrasion Test determines the Abrasion Index, which is used to determine steel media and liner wear in crushers, rod mills, and ball mills.

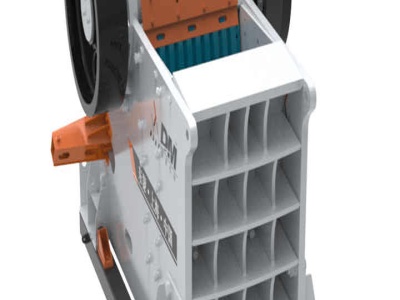

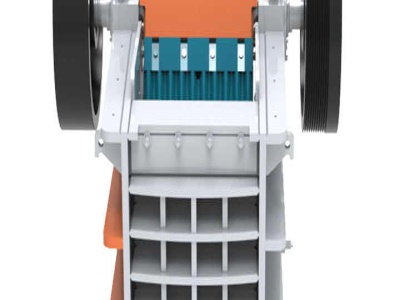

(PDF) SIZE REDUCTION BY CRUSHING METHODS

There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4 ...

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Grate Ball Mill,Overflow Type Ball Mill,Ball Milling ...

Ceramic Ball Mill is mainly used for mixing, milling of the material, the fineness even saving force. Not only the wet mill, but also wet mill. The machine could use the different line according to the product requirement to satisfy different requirement.

Ball Mill Working Principle And Main Parts

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

SmallScale Tests to Characterise Ore Grindibility

also be closed with various sieve sizes, but for AG/SAG mill analyses the standard 14mesh () sieve is typically used. The rod mill work index is computed with an equation very similar to that of the ball mill test, as follows: It is common to observe a difference between the rod mill and ball mill values for a given ore type. These ...

ball mill index for various materials

ball mill index for various materials ball mill index for various materials. Granite Crushing Plant in Sri Lanka Pebble and Basalt Production Line in Panama Laos iron ore processing plant Limestone and ...

Ball Mills

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral ...

Mining Mill Balls

Ball Mills JXSC Mine Machinery. Jan 30, 2018 · Ball mill for sale In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatment.

Why highgrade iron ore is set to outperform other grades ...

· Mill profit margins also ebbed, reducing the incentive to maintain such high output. Stocks of iron ore at main Chinese ports have recovered to preCovid levels. On the supply side too, iron ore output has been steadily increasing as miners endeavor to respond to the highprice environment.

Why gold mines are adopting HPGRs to ...

· For gold mines using carboninleach (CIL) processes for recovery, we've found the best results are achieved with a HPGR performing tertiary grinding before a ball mill further reduces the product. In this role, the HPGR significantly uplifts the capacity of the circuit and provides flexibility both in dealing with feeds that a ball mill would struggle with, and the product quality required ...

Ball Mill

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Gongyi Hengchang Metallurgical Building Material ...

Energysaving Ball Mill Ore Grinding Mill 1200x2400mm. 6, 150, / Set. Sets ... Mining Ball Mill Gold Ball Mill Grinder Machine Fine Grinding Ball Mill for Mines. 9, / Set. 1 Set ... plaster powder and other materials into a balls/ briquettes, ...

ball mill index for various materials

ball mill index for various materials Products improvement Table of Bond Work Index by MineralsThis Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample'. You can find the SG of each mineral samples on the other table.

Latest Posts

- سعر محطة كسارة الحجر tph

- قائمة مصنع للاسمنت في ساتنا

- المطرقة محطم وصف

- PE 150 و 250 كسارة الفك مصنع الصين

- محطات تكسير كاملة

- قيمة التأثير لجسر الخرسانة

- مزايا كسارة الفك على كسارة الفك

- مجموع محطم آلة المملكة العربية السعودية

- المطرقة مطحنة للبيع الفلبين

- وحدة تكسير الكلنكر 100tpd في مصر

- حجر صغير السعر محطم ل بيع

- موردي كسارات الفك في الجزائر

- سعر الشاشة بالاهتزاز

- كيفية تصميم آلة طحن الحجر في المملكة العربية السعودية

- بيع كسارة ميكا متنقلة

- impact gold crusher granite

- specialist concrete breaking equipment

- harga pet kokas pabrik grinding

- utilisé des pièces de calcaire broyeur vertical

- permenant magnite for crushers appliions

- crusher mobile plant photo images

- track mobile jaw crusher

- gold gold mining jaw crusher for sale

- svedala gold flotation cell for sale

- long distance aggregate conveyors for

- home made rock crusher samson

- tige de tension de concasseur à mâchoires pe750 1 060

- best mill grinder

- used lucas sawmill for sale in brooklyn

- energy saving complete equipment for cement manufacturing line