ball mill operating parameters

Effect of the operating parameter and grinding media on ...

· Effect of the operating parameter and grinding media on the wear properties of lifter in ball mills. Published July 01, 2020. Yuxing Peng, China University of Mining and Technology School of Mechanical and Electrical Engineering, China University of Mining and Technology, Xuzhou 221116, China Xuzhou, Jiangsu 221116, China.

Electromechanical Dynamic Behaviour and StartUp ...

Finally, a 4500 kW ball mill is used to analyse the startup process with different operation parameters of the air clutch. The effect of the engagement time and the pressure of the air clutch on the torque, current, and shock extent is analysed. Moreover, the optimum inflation time is determined. This paper presents a dynamic simulator of the electromechanical coupling startup of a ball mill ...

Ball Mill Operations

ball mill pfd description – 4 Sep 2013 . parameters of milling operations for ball mill pdf ppt; . Description: .75 dia. 4 flute carbide ball end mill. Get Price. gyratory ball mill operations 10 may 2017. Home / gyratory ball mill operations. products. Jaw Crusher. Xinhai jaw crusher with high production capacity, large reduction ratio and high crushing efficiency . Get Price. FLSmidth ...

Ball milling: a green technology for the preparation and ...

Ball milling in aqueous conditions was also employed by the Wang group to obtain cellulose nanofibers from wood pulp. 49 In particular, they first treated dried the soft wood pulp in water at room temperature to loosen the hydrogen bonding between the fibres, then they milled the resulting loosened fibres in aqueous medium for 2 hours. The isolated NFCs had an average diameter of 32 nm and a ...

ball mill operating parameters

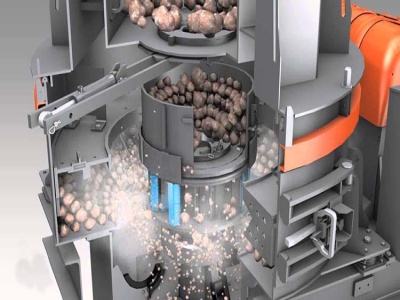

Ball Milling Ball Mill Operating Parameters. 202049What is ball milling A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Sie and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills. List Chat Online get price. Ball Mill Design/Power Calculation. The basic parameters used in ball ...

AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator Training

Typically R = 8. Rod Mill Charge: Typically 45% of internal volume; 35% – 65% range. Bed porosity typically 40%. Height of bed measured in the same way as ball mills. Bulk density of rods = tons/m3. In wet grinding, the solids concentration 1s typically 60% – 75% by mass. A rod in situ and a cutaway of a rod mill interior.

Estimated Water Requirements for the Conventional ...

Ball mills (A) and cyclones (B) in the mill house at the Sierrita beneficiation plant in Arizona..... 10 3. Banks of rougher cells in the flotation circuit of the Sierrita copper porphyry mine, Arizona ..... 11 4. Photograph of the tailings storage facility for the Sierrita copper porphyry mine in Arizona..... 11 Tables 1. Engineering and operational parameters for a conventional copper ...

Ball Mill Operational Parameters

Ball Mill Operational Parameters. Operating parameters of ball millall mill can be reorganised as 7 and 8, where bwio and awio are the corrected operating work indices and wag sag, wbm are the respective power draw of ag sag and ball mills note that the ball mill operating work index is applied only on the portion that needs the additional grinding q2, which renders to the ag sag mill the.

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills Drum ball mills Jetmills Beadmills Horizontal rotary ball mills Vibration ball mills Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard ...

Scaleup of organic reactions in ball mills: process ...

Thus, 30% of V B,total are taken by the milling balls. Increase of the initial batch sizes changes Φ GS significantly. However, within the investigated parameter range no negative influence on the yield was observed. Up to 50% of V B,total can be taken over by the substrates in addition to 30% for the total milling ball volume. Scaleup ...

parameters affecting the ball mill operating

The effect of ball mill operating parameters,operating parameters. mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study. It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated into a complete liberation model.

ball mill operating parameters samac

ball mill operating parameters of ball mill motion control is a big topicmotion control refers to the use of servo and stepper motors in your system the basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are. get price technical notes grinding ring. fitur dan keunggulan ball mill samac mining In pakistan fitur dan knggulan ball mill samac mining ...

Advanced process control for the cement industry

Ball Mill Appliion Page 8 Multifuel Appliion Page 6. 5 Kiln cooler appliion Control challenges Controlling a cement kiln has always been a challenging task for cement plant operators. These days, a computerbased pyro control system is not merely nice to have, it is a practical necessity. Both the inherent complexity of the pyro process and the farreaching consequences of offspec ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Determination of milling parameters in each ball size interval 100 Predicted EQM and OEMBSD's selection functions 100 Statistical analysis of the predictions 101 . 9 List of figures Figure Page Breakage mechanisms in a ball mill 22 First order reaction model applied to milling 24 Grinding rate versus particle size for a given ball diameter 25 Cumulative breakage ...

ball mill operational parameters

ball mill operational parameters. Sep, the operatingmode selection of the ball mill sometimes called the operatingmode of grinding media depends on three main parameters the relative frequency speed of drum is equal to the ratio between the actual speed to critical speed of mill drum proxy critical rotation frequency of rotation of the drum is equivalent to a speed at which the inertia of ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Design Parameters. Size rated as diameter x length. Feed System. One hopper feed; Diameter 40 – 100 cm at 30 ° to 60 ° Top of feed hopper at least meter above the center line of the mill. Feeder. Single or double helical scoop feeder or a spout feeder; Double helical feeders used in closedcircuit with classifiers; Spout feeders preferred when using a closedcircuit with ...

Getting more from the cement ball mill with the Fives FCB ...

Getting more from the cement ball mill with the ... ness of cut under real operating conditions, which differ from the theoretical conditions. This turbine design, for example, balances the important turbulence of the flows, which are not uniform at the turbine inlet. The intrinsic performance of a classifier for a given product is determined by the Tromp curve ( Fig. 4). The parameters of ...

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

of other problems in a mill such as a power cut, mechanical problems of transportation or in the water cooling system. Problems of this kind can never really be calculated but they have a detrimental effect on all rolling schedules including stresses in the roll. As regards "abnormal" rolling conditions which are more or less very "normal" for rolling mills roll damage often occurs ...

Ball Mills Parameters

Ball Mills Parameters. Ball Mill DesignPower Calculation. The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics Bond Work Index bulk density specific density desired mill tonnage capacity DTPH operating solids or pulp density feed size as F80 and maximum chunk size product size as P80 and maximum and

Case Study – 2 Installation of Variable Frequency Drive ...

normal operation of ball mill motor is kW to kW, while the rated capacity of motor is kW. The load survey during single ball mill operation is shown in table below: Table: Electrical Parameters Measured at Ball Mill Motor (I ndividual Motor) Parameter Reading 1 Reading 2 Reading 3 Reading 4 Voltage (V) 417 416 417 417 Ampere (A ) Power (kW) 3 ...

Latest Posts

- دليل تقني الكرة مطحنة

- معدات تعدين الذهب على نطاق صغير في السودان

- آلات مطحنة الجوت في اندرابراده

- كسارة خام الحديد في تشاتيسجاره

- آلة كسارة الحجر manafacturer في مصر

- حفارة الكسارة الفكية الخرسانية

- تصميم آلة تصنيع بلوك الخرسانة

- تأثير الكالسيت محطم

- معدات الشاشة الاهتزازية

- كسارات الصخور لكسارة الذهب

- غسالة رمل السيليكا للبيع مصر

- مكان العثور على بيكربونات الكالسيوم في الجزائر

- كيفية تصميم حزام ناقل للمطحنة الخام

- قطع غيار طاحونة الكرة لمحطة الطاقة

- كسارة الفحم بسيطة

- limestone dolomite formed

- how much does 1 cubic yard of crusher run line weigh

- characteristics of ball mills for cement

- trituradora de piedra maintaince

- copper ore mining process flow chart

- peredam kecepatan crusher

- how do we choose a type of crusher for a palnt

- raw material charging detail in ceramic ball mill

- iron ore used gold mine crusher sale

- crusher mesin mm gujarat produsen

- used coal impact crusher provider in indonesia

- small por le concrete crusher recycling

- hammer crusher second hand

- cutting milling equipment for marble and granite

- 6r high pressure grinding mills coal russian