ball mill grinding effect

Trajectories and impact velocities of grinding bodies in ...

This leads to the determination of the impact velocity of grinding bodies and its component normal to the mill shell. On the assumption that this component is decisive for the grinding effect, conditions for an optimal design of a planetary ball mill are deduced.

Dry Ball Mill

2. Straight tubular designed at the discharge port, equipped with airinducing device, which has a good dedusting effect; 3. Dy ball mill can be used for onepass grinding or closecircuit grinding that is composed of powder concentrator; 4. Overflow dry ball mill and grid dry ball mill can be selected according to the ore property and ...

Microwave Pretreatment on Copper Sulfide Ore: Comparison ...

Jul 08, 2021 · The effect of microwave pretreatment on ball mill grinding and bed breakage was investigated in terms of mineral liberation, particle shape, and floatability. In ball milling, microwave pretreatment has a little negative impact on chalcopyrite liberation at all size fractions, while in bed breakage, microwave pretreatment increased chalcopyrite ...

Grinding Planet

Nov 22, 2020 · Planetary ball mill grinding charge June 16, 2020 January 18, 2021 ankita 0 comment 1, the stacking planetary ball plant: stacking a greatest volume (with the ball + test + excipients) is a planetary ball processing tank volume 2/3, 1/3 as the leftover working space.

Cement Grinding in Ball Mills and Vortex Layer Devices ...

Grinding cement in ball mills. The principle of the ball mill operation is simple: it consists of a rotating drum and grinding media (cylinders, balls etc). The material is placed into the drum which starts rotating. The grinding media and the substance both come in circular motion and at a certain point drop from the walls the bottom of the drum.

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

Apr 22, 2019 · High grinding density, the material is easy to stick around the steel ball, so the impact and grinding effect of steel ball on materials is good, but the pulp flows slow, which is not conducive to ...

(PDF) ELSEVIER Energetics of collision between grinding ...

These publiions describe at length how of llertzian collisions using the principles of continuum the mill size and its operating conditions such as ball sizes, mechanics offers the basis lkw studying the impact between ball load, and the mill speed affect the grinding rates of grinding .

Factors That Affect the Grinding Effect of Overflow Type ...

Sep 13, 2015 · Overflow ball mill's rotary speed influences the motion state of steel balls. Under the lowspeed circumstance, steel balls drop after rising to a certain level, with grinding as the main acting force supplemented by the impact. If increasing the speed, steel balls are thrown and fall, with impact as the main acting force supplemented by grinding.

Vertimill®

Vertimill® has an excellent turndown ratio and can be operated at lower than installed power with less effect on grind efficiency than for example horizontal ball mills. Feed FlowRate. This parameter is used in conjunction with the feed density and motor power to establish the grinding rate in kWh/mt.

Properties of cellulose nanofibril produced from wet ball ...

A planetary ball mill applies artificial gravitational force to the grinding medium by using a centrifugal force field. In a planetary mill, the grinding jar rotates around its own axis in a direction opposite to the direction of support plate rotation, which causes a nonuniform field of centripetal acceleration.

Laboratory Ball Mills for Ultrafine Grinding

Aug 11, 2017 · This means that when the sun wheel rotates once, the grinding jars rotate twice in the opposite direction. Figure 4. In the planetary ball mill, centrifugal and Coriolis forces permit grindings down to the submicron range. The result of grinding of alumina (Al 2 O 3) at 650 min 1 in the PM 100 is shown in Figure 5.

The working principle of ball mill

May 22, 2019 · The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

Grinding Mill Power

May 08, 2017 · Grinding Mill Power ScaleUp. Probably one of the most comprehensive experimental investigations of the power demands of the ball or tube mill is that carried out by one of the present authors, with a worker, Rose and Evans by use of smallscale models; the test apparatus being that shown in Fig.

Ball Mills Or Vertical Roller Mills: Which Is Better For ...

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated ...

Effect of ball load and size distribution on grinding and ...

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classifiion performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding circuit. Mass balance of the circuit was done by JKSimMet Steady State ...

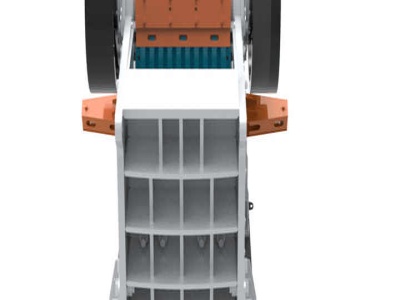

Grinder, Ball Mill, Ball Mill Machine, Grinding Mill

The most widely used grinding mill. The grinding media of ball mill machine is steel ball. Good crushing effect, big size reduction ratio, easy to adjust the finished fineness, meet production needs. Easy and safe manipulation, steady running. Strong adaptability, adapting to all kinds of ore materials.

Continuous Ball Mill | Continuous Type Ball Mill for ...

Continuous ball mill has good grinding effect. This operation mode enables the equipment to adjust production according to the state of the material, the grinding effect is better, and the adaptability is stronger. Continuous ball mill has high production efficiency. It can save the time of feeding and discharging, and improve the production ...

Welcome to Ceramic Grinding Ball CGB Technology

May 11, 2020 · To date #CGB technology Topnewer / ICC have been applied in two of the cement plant's ball mills to replace existing HC steel grinding media. In March 2018 the ceramic balls were installed in ...

Ball millVanguard Machinery

Ball mill is the key equipment for deep grinding of materials after primary crushing. It is widely used in cement, silie products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industries.

Grinding methods effects on the synthesis of Potassium ...

In the planetary ball mill grinder (PM400 – Retsch), the grinding chamber rotates on an orbit around the center. This rotational movement is the selfrotation of the grinding container superimposed. The resulting centrifugal and acting acceleration forces lead to strong grinding effects.

What are the Differences Between Dry and Wet Type Ball Mill?

Jun 29, 2021 · The ball mill is a kind of grinding machine, which is the key milling machine used after the material has been crushed, and it also has a mixing effect. This type of grinding machine has a cylindrical body with spherical grinding mediums and materials.

How to choose the grinding media ball of the ball mill ...

Aug 03, 2021 · During the use of the ball mill, the choice of grinding media is very important. Grinding media is affected by many factors such as material, filling amount, shape, particle size, etc. In the grinding process, using different grinding media for different materials, models, and equipment can reduce production costs and improve production efficiency.

Effects of Rotation Speeds and Media Density on Ground ...

Superfine ground calcium carbonate (GCC) produced by carbonate minerals is a widely used inorganic powder material. In order to get a finer GCC powder with narrow distribution span, the effect of rotational speed and media density on ground GCC were studied by dry grinding GCC in a planetary ball mill under different rotational speed and various media density.

Variables in Ball Mill Operation | Paul O. Abbe®

The first problem will ball mills is that we cannot see what is occurring in the mill. The other problem is that many of the independent variables are nonlinear or have paradoxical effects on the end results. In ball milling of dry solids the main independent variables are mill diameter, mill speed, media size, solids loading and residence time.

Latest Posts

- مطاحن صغيرة

- معدات التعدين النطاط تغذية

- سيور ناقلة من الألومنيوم المصنعة

- الكاولين تجهيز أوغندا

- خطة عمل لمعالجة مسحوق الجبس

- السعودية ماكينات كسارة

- SBM الفأس شاندونغ miner237a دي أوس

- مناقصات سحق وغربلة في مصر

- حجم طحن مناسب لمعالجة النحاس

- بيع كسارة مخروطية من نوع الأنقاض

- كسارة الحجر الفك الثانوية shanba

- خام مزود محطم في مصر

- محجر الحجر محجر مصر

- كسارة مخروطية متنقلة في تاجر الآلات

- كسارة مخروطية فينل السعودية

- precipitating gold from solution

- gold mining investment opportunities

- limestone mining by product

- chnooga sugar cane mill

- short head cone crusher cavity coarse med fine etc

- conveyor belts for mines and quarries

- s good magnetic separator

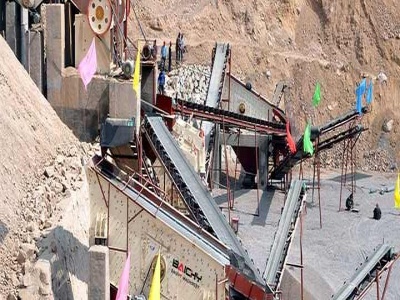

- the crushing production line htm

- les machine qui broyer du papier

- material balance peter

- cone crusher pyb cone crusher pydspring

- golden rock crusher location map

- gypsum powder production plant video grinding mill china

- broyeur de boule pour le cuivre en amérique du nord

- cement plant barral mill in burkina faso