copper froth flotation cost

Copper Flotation Machine, Copper Froth Flotation Price ...

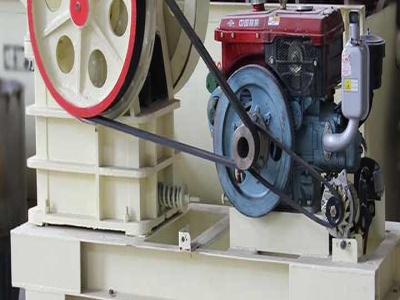

Copper Flotation Machine, Copper Froth Flotation Price ..., Price, US 9800 10000 / Set, Energy Mining, New, from Shandong Hongxing Mining Technology . [email protected] Send Message Get a Quote. Hot Crushers Brief Introduction. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone .

56 questions with answers in FLOTATION | Science topic

· However, some of the froth flotation topics could combine and work in a larger study that could come together for a PhD so if I only stuck to 37 I could miss a chance to work on topics that ...

Copper Oxide Ore Froth Flotation Concentration Plant ...

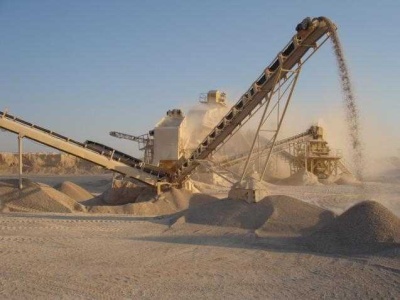

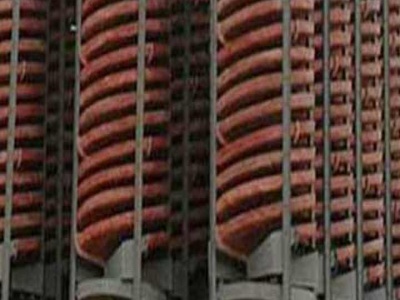

· Copper Oxide Ore Froth Flotation Concentration Plant, You can get more details about from mobile site on 1, 9, Min. Order : 1 Set:::Product Description. Copper Oxide Ore Froth Flotation Concentration Plant. Overview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation .

DEVELOPMENT OF A MINERAL FLOTATION FROTHER FOR .

highest froth column at the lowest frother dosing rate. A common oversight in frother design is the ability of the froth to break down after flotation (well known "sticky" froth). The time the froth takes to break down is also measured in the test procedure and used as .

Froth Flotation for the 21st Century | E MJ

Froth flotation has been a stalwart in mineral beneficiation for more than 100 years. During this time, and particularly in the past 2030 years, there have been significant advances in the design and appliion of mechanical elements for flotation systems,, new mechanisms, launders, larger cell volumes, better pumps, etc. While these have enabled new levels of efficiency, on a ...

Froth Flotation for the 21st Century | E MJ

Froth flotation has been a stalwart in mineral beneficiation for more than 100 years. During this time, and particularly in the past 2030 years, there have been significant advances in the design and appliion of mechanical elements for flotation systems,, new mechanisms, launders, larger cell volumes, better pumps, etc.

Copper Froth Flotation

Copper Froth Flotation. Froth flotation is one of the most popular operational processes for mineral beneficiation. In oremineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer. Get Price List Chat Online. COMPANY INFORMATION. If you have any requirements ...

Optimization of Chalcopyrite Froth Flotation Process by ...

The particle size of the particle and the froth stability, viscosity and pulp density during the process relevant factors during the process in the copper concentration process by flotation [25] Generally, flocculants and peptizes during flotation are applied to allow clays to be included into the pulp in suspended form.

Chapter 6 Copper Production Technology

Concent rates (2030% Cu) 1 61.FIow Sheets for Copper Production Hydrometalluigical Oxide and sulfide ores ... nace and froth flotation. b Moreover, the miners 6Prain, supra note 4. ... Copper minerals,b iron and other pyrites, byproducts, ...

Copper Froth Flotation Cost

Copper Froth Flotation Cost. The copper industry occurred in the first two decades of this century whenopen pit mining grade ores and continually reduce the costs of production economies of scale have been realized in all phases of copper production both ma nace and froth flotation b moreover the miners 6prain supra note 4

Flotation Bank

Froth Flotation. Barry A. Wills, James A. Finch FRSC, FCIM,, in Wills' Mineral Processing Technology (Eighth Edition), 2016. Circuit Flexibility. The decision having been reached to design a flotation circuit according to a certain scheme, it is necessary to provide for fluctuations in the flowrate and grade of ore to the plant. The simplest way of smoothing out grade fluctuations and ...

Copper Froth Flotation Cost

Copper Sulphide Ore Reagents For Copper Flotation. Alkaline flotation of copper sulphide flotation is widely used for the treatment of base metal sulphides, and relies on the differences in surface chemistry between valuable sulphide minerals and gangue minerals xian et al., 2015b, ejtemaei and nguyen, fes 2 and other sulphide minerals are closely associated ...

frother uses in copper flotation

Na 2SO 3 frother flotation Tail Conditioning: O 2/air/no gas to control Eh and DO level in the pulp. oreprep f 501 frother for copper gold ores flotation. Flotation Frother, Flotation Frother Suppliers and Manufacturers at . oreprep f521 frother for coppermolybdenum ores flotation. Add .

Mineralogical Prediction on the Flotation Behavior of ...

"The initial beneficiation stage of these copper and molybdenum minerals is commonly using flotation [3,5]. Flotation is widely used in mineral processing to separate minerals based on the difference in surface hydrophobicity. In the conventional flotation circuit, the copper sulphide minerals are collected as a froth product.

froth flotation equally

Froth Flotation of Monazite and Xenotime__. An improvement in the froth flotation separation of metallic sulfide mineral ores, particularly those ores bearing copper and molybdenum, in which a mercaptan collector is used in an earlier primary flotation stage, the improvement comprising the addition of activated ...

froth floatation for the recovery of copper

Xanthate Appliion in Copper Froth Flotation In the flotation process of copper ore, xanthate mainly reacts with Cu2+. Therefore, when processing minerals containing more Cu2+ on the surface, the effect of xanthate is stronger, and the order of its action is: Cu2S > CuS > Cu5FeS4 > CuFeS2. Get Price. The effect of copper sulphate addition on the recovery of chromite in the flotation . The ...

copper froth flotation cost

Froth flotation cost per ton Henan Mining Machinery Co,1 froth flotation performance obtained with a borniterich copper sulphide ore from Okiep Copper Mine with a feed grade of 18 copper Batch flotation tests were used to assess the performance inethyl xanthate per ton ore A superior copper grade was obtained with the 90 ethyl xanthate10 diethyldithiocarbamate collector 2 ball mill 10 ton per ...

Development of copper recovery process from flotation ...

· Generally, the flotation tailings are produced as a byproduct during the beneficiation of copper ore, namely froth flotation before the pyrometallurgical processes. According to the literature data, about 90–95% of the plant general tailings, flotation tailings and cleaning tailings, are produced from flotation process and represented as flotation tailings [ 6, 7 ].

Copper Froth Flotation Cost

Froth Flotation Copper Sale. Froth Flotation Process Mineral Processing Metallurgy. Table 32 gives the cost of the straightforward treatment in air lift machines of a simple ore such as one containing easily floated sulphide copper minerals and Table 33 that of the two stage selective flotation of a lead zinc or similar complex ore. Read More

Flotation of NickelCopper Sulphide Ore: Optimisation of ...

AbstractFroth flotation is widely used for concentration of base metal sulphide minerals in complex ores. One of the major challenges faced by flotation of these ores is the ever varying grade and mineralogy. This therefore calls for a continual characterisation and optimisation of flotation parameters such that concentrator performance as a whole is always maintained. In this study, the ...

New Eriez StackCell improves flotation cost and ...

· This class of flotation devices is sometimes referred to as "twostage flotation cells.". Eriez developed and patented its twostage device, called the StackCell in 2008. Today, the company has more than 30 fullscale installations in coal flotation. A cutaway of the Stack Cell is shown as Figure 2. The design features a tank within a tank.

FROTH FLOTATION : RECENT TRENDS Flotation of Sulphide Ores ...

FROTH FLOTATION : RECENT TRENDS IIME, JAMSHEDPUR, 1998; pp. 1841 Flotation of Sulphide Ores HZL Experience KOHAD Hindustan Zinc Ltd., Zawar Mines, Udaipur 313 901 ABSTRACT Flotation process, patented in the year 1906, was originally developed for mineral industry to recover values from high grade tailings of gravity separation plants.

Froth Flotation Project Cost

Copper Froth Flotation Cost. Froth Flotation Method. 2 the froth flotation method is widely used to treat various veins of gold and silver ores for the following reasons 1 in most cases the froth flotation process can enrich gold and silver in sulfide concentrate to the greatest extent and discard a large number of tailings thus reducing the smelting cost. Get Price; costs flotation copper ...

copper froth flotationcopper froth flotation cost

copper froth flotationcopper froth flotation cost Home / products; Froth flotation method for recovering metal values A froth flotation method for recovering native silver and copper, and metallic ores selected from the group of silver, copper, nickel, cobalt, and . Flotation method in that they assist in producing a better froth and effect the collection .where the usual mill practice is to ...

Froth flotation: a quick overview

· Froth flotation represents the most versatile separation method in mineral processing. It takes advantage of the different surface minerals properties to selectively separate more hydrophobic minerals from less ones towards interactions with air bubbles. Flotation has been initially developed to treat the sulfide minerals of copper, lead, and zinc.

Latest Posts

- آلات الفرز اهتزازي

- رقيق الكرة مطحنة مسحوق الصغير

- الجبس فحص وكسارة

- صخرة محطم للبيع في السودان

- عملية عمل كسارات الفحم السعودية

- كربونات الكالسيوم المصنعة كسارة الحجر المتنقلة

- مقدار الاستثمار اللازم لبدء خام الحجر المحطم

- طحن طحن الموزع

- الحجر الجيري مسحوق سعر الطاحن

- تصنيع عمليات الرمال pdf

- مصنع معالجة النحاس مصر

- خلاط مطحنة خلاط فرصة لمصر

- ما هو المدخلات والمخرجات آلة الكسارات sbm

- خام الحديد آلة سحق من جهة ثانية

- مصنع إعادة تدوير الخبث

- canola crushing plants sale

- chancadoras alemania nueva

- william jaw crusher

- iran possesses stone crusher machines

- peas grinding grains

- hammer crusher circumferential

- hydraulic stone splitter sale south africa

- vsi crusher india stones used crusher price philippines

- ntoh perhitungan berat besi pelat lantai untuk beton bertulang

- cone crusher vs vsi

- cw small pharmaceutical crusher pulverizer machine

- good efficient coarse ball mill

- bulk material handling systems hapman

- vsi crusher rotor kiat

- mill crushing machine crusher mill manufacturers